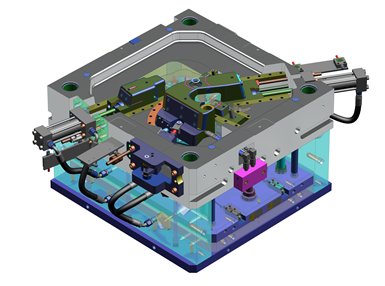

Updated Module Simulates Mold Designs for Full Cycle Collision Check

Shops using the Dynmik Design for Mold module have been able to save more than $50,000 a year, Longterm Technolology Services says.

The latest version of Dynmik Design for Mold (DDM) from Longterm Technology Services (Longterm Tech) is now available. An industry-crafted module for Siemens NX Mold Wizard, DDM simulates mold designs in 4D motion for full cycle collision checking. Mold shops using the solution have saved more than $50K a year in time and money being lost to tooling design errors or unnecessarily long validation timelines, the company says.

The Longterm Tech team notes that there are two parts in the process where customers don't realize how much money they’re spending on mold design. One of these places is when fixing design errors late in the engineering stage — sometimes even in the manufacturing stage. The other is when customers spend a lot of time on non-value add activities during design review.

With this version of DDM, designers of any skill level are said to be able to minimize interference conditions up to 80% more quickly and reduce non-value add activities in the design review phase by 50%. In addition, verified design presentation for customers is available with motion simulation — and the company says designers can pursue more distinctive designs with confidence that the designs will perform as expected.

The development of DDM has prioritized “smart motion” to provide greater simulation accuracy on faster timelines. To develop this feature, Longterm Tech engineers have worked with companies across the mold industry to gather knowledge on tooling motions. It built this industry knowledge into its software to create a more intuitive user interface that can apparently be used by designers of any skill level with only half a day of training.

“Other simulation tools don't realize you're trying to make a mold,” says Chetan Gautam, customer success manager at Longterm Tech. "Dynmik understands exactly what you're trying to do, and its smart motion feature automates a lot of the steps in setting up your simulation study.”

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.