TST Tooling Software Releases TSTracker 10.2

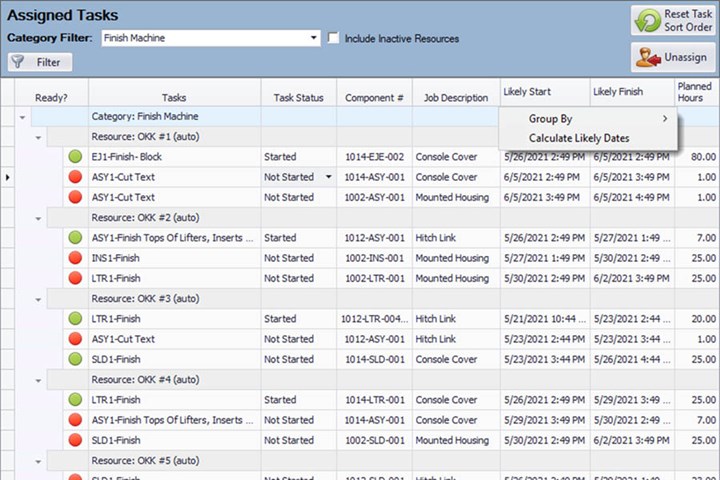

The ERP software update, to be demonstrated at Amerimold, covers a range of new and optimized features for enhanced customization and tracking capabilities.

Photo Credit: TST Tooling Software Technology

TST Tooling Software Technology will be demonstrating the new release of its enterprise resource planning (ERP) software designed specifically for moldmakers and manufacturing, TSTracker 10.2, at Amerimold 2021.

Users can expect new and optimized features with this update, beginning with its completely reorganized menu system for easier access to new features and settings. A new Cost Detail tab with a new and improved Labor Hour Report instantly identifies labor overage by department. The Auto Time Import feature provides real-time reporting of time tickets from a user’s time-tracking software and improved Labor Costing. Accounting Exports are said to eliminate double entry, export vendor purchase orders via a user’s GL numbers, give the ability to customize imports for any Accounting Package and also features SAGE Accounting Import.

Added features include new Multi-Currency features such as the Exchange Rate configurator, Quote Footer customization for legal terms on a printed quote and the ability to automatically add material lists from Estimator to the Job Bill of Materials (BOM).

Multiple estimate formats range from mold, die, secondary machines and now include machining.

Exhibitor: TST Tooling Software Technology

Booth 407

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.