Tooling: New Mold Components at Fakuma Show

Automatic safety locks, mold status indicators, hose manifold blocks, online ejector configurators, and new flexible lifters.

Three suppliers of standard mold components showed off additions to their lines at October’s Fakuma 2018 show in Germany. A handful of new components from Hasco includes safety couplings (Z80700HT to Z80801HT) with an automatic safety lock that protects against accidental unlocking, while still ensuring easy decoupling. A deliberate unlocking movement required of the rotating guide on the locking sleeve, and a clearly visible green color coding behind the locking sleeve indicates correct and safe coupling.

Another introduction is Hasco’s A5850 mold status indicator, which can be attached to a mold by screws or magnet. A knurled wheel allows changing a color indicting band, without tools. Four colors indicate whether a mold is ready for use, needs maintenance, is ready for sampling, or is out of service.

New Z21 centering sleeves are said to be a simple and flexible means to precisely align plates on injection molds as they are joined together. Hasco notes the sleeve’s space-saving position above the buildup screw connection, which is further facilitated by a 15° lead-in chamfer.

Other new Hasco products include Z2302 positive locking cylinders for valves and cores, with mechanical end-position detection and suited for use at up to 180 C/356 F. New Z920 manifold blocks allow simple configuration of flexible cooling hoses with a clear arrangement of feed and return lines. The new Z086 flat locating unit for high-precision molds supplements conventional guide pillars and bushings. New flat ejector pins have extra blade length and either no corner radius (Z4670) or four corner radii (Z4671). Mold plates are now available in a pre-hardened steel, 1.2714HH. With a maximum hardness of 400 HB, it offers good machinability, dimensional stability and toughness while requiring no additional heat treatment.

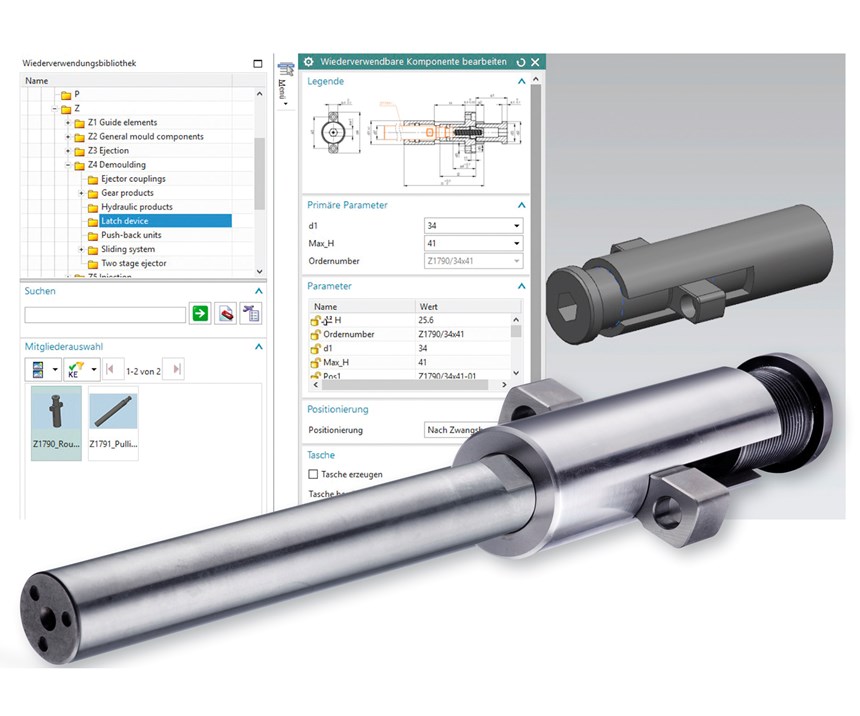

And when it comes to configuring tooling on a computer, Hasco customers now have direct access to the Hasco NX library of native CAD data in Siemens NX format. Downloading the entire library allows design by drag-and-drop and makes it much easier to switch components than if users had to download individual products one by one.

Meanwhile, Meusburger has introduced a new online custom ejector configurating and ordering capability. Among many new components available now in stainless-steel are safety couplers, quick couplers, and vent valves. The company also brought out DLC-coated guide plates, larger tunnel-gate inserts, and additional sizes of guide pillars (standard and DLC coated), as well as a range of non-metric “USA System” components. New E 1675/1676 sprue adjusters are round plugs for blocking off cavities; accessible from the split-line face, they can be rotated with a hex wrench to open or close off runner channels.

The latest in undercut-release components from CUMSA are new flexible lifters consisting of a jacketed steel coiled cable. They allow angles up to 6°, while CUMSA’s rigid, double-rack lifters cannot go below 8°. The smaller Smart Worm Pin is suited to ejector strokes of 30 or 60 mm and undercuts up to 6.3-6.4 mm. The larger Smart Worm Lifter is sized for 100- or 125-mm ejector strokes and up to 145-mm undercuts.

Related Content

Large Mold Mounts Eliminate Shop Floor Hazards

Progressive’s new 5-inch-tall RhinoFeet safely supports 15,000 lb each.

Read MoreCMMs Give Moldmakers Precision, Sustainability, Ergonomic Operation

The new generation of Zeiss Prismo precision measurement devices meet speed, flexibility, sustainability and productivity demands.

Read MoreCertified Quality Management for Plastics Professionals – Materials to Tooling to Recycling

Why is certification of a shop’s quality management system to ISO 9001, AS9100, IATF 16949 or ISO 13485 so special? What does the certification signify? And what supports the paper behind the framed certificate?

Read MoreTool Caddy Safely Stores Cutting Tools

The Kaiser Manufacturing Tool Caddy makes it convenient for the operator to grab toolholders without any risk of cuts.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More