Thread Formers Offer Enhanced Performance, Surface Finishes

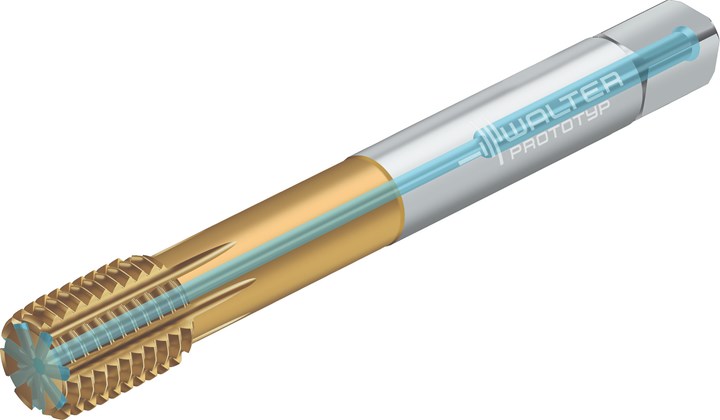

The Walter TC420 Supreme has been optimized for maximum performance in universal applications, with high performance and 30% less torque.

Photo Credit: Walter USA

Walter USA presents the TC420 Supreme thread for universal use. The HSS-E-PM thread former, with a high number of forming edges, produces high cutting speeds with up to 30% less torque, good surface finish and improved lubrication. The TC420 Supreme includes one configuration with chamfer form E (M5–M16) for blind-hole threads up to 3.5×DN, which uses a combination of chamfer form E with axial internal coolant and without lubrication grooves.

A new feature of the TC420 Supreme metric version, now up to M24 dimensions (metric fine M8x 1-M16 x 1.5), includes radial internal coolant for blind-hole and through-hole threads, optimized for maximum performance in universal applications.

In addition to high cutting data and long tool life, the thread formers feature higher break-out resistance under dynamic load compared with other threading techniques, according to the company. Walter offers the TC420 Supreme thread formers for medium to large batch sizes with and without lubrication grooves, as well as with axial or radial internal coolant, and without internal coolant. Tool coating options are either TiN coating (WW60AD grade) or TiCN (WW60BA). Typical areas of application include general metalworking as well as the automotive and energy industries, for ISO materials P, M, K, N and a secondary use in ISO S materials.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.png;maxWidth=300;quality=90)