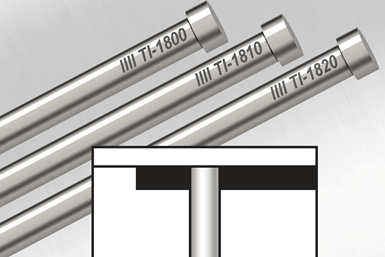

Thousandth Increment Pins Designed for Small Cavity, Core Inserts

Progressive Components’ TI Pins offerings now include 267 standard sizes.

Progressive Components announces the recent expansion of its line of TI Pins, which now include 267 new standard sizes offered in new, longer lengths.

Unlike stamping punches, which are sometimes used as core pins in molds, Progressive’s exclusive TI Pins feature heads that are precision ground to mold tolerances. Also, rather than beginning with a fractional-diameter core pin, step grinding can be eliminated with mold inserts attached to the molded part diameter via wire EDM, requiring TI Pins only to be cut to the finished length.

Designed to fit into small, crowded cavity and core inserts, Progressive’s TI Pins are manufactured with hardened M2 steel and available in diameters from 0.060" to 0.320" in 2.5" and 5.5" lengths. Cut-to-length and custom options are also available.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=300;quality=90)