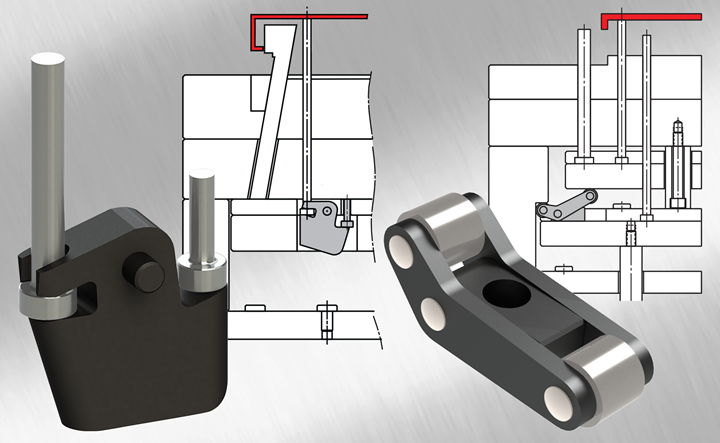

Mold Ejector Accelerators Achieve Second-Stage Ejection

Progressive Components says its Ejector Accelerators can be used when additional pin travel is required to release molded parts from lifters, stripper plates or deep core features, without the need for a second set of ejector plates.

Photo Credit: Progressive Components

Progressive Components has introduced Ejector Accelerators, featuring a compact footprint that’s sized for inch ejector pins and ejector plates. The product is designed to create a second-stage ejection without the need for a second set of ejector plates. Actuating an ejector pin forward movement, the product can be used when additional pin travel is required to release a molded part from lifters, stripper plates or deep core features.

Progressive says the Ejector Accelerator has robust strength despite a thin and compact footprint. This efficient design enables it to be situated between a mold’s other features, including lifters, support pillars and ejector pins.

Ejector Accelerators are available in four standard-inch sizes and include a kicker pin and dowel pin installed. Progressive says this product further builds out the company’s Plate Sequence Control program and is joined by a rocker-style Plate Accelerator for double ejection applications, along with additional sizes of Latch Locks for large multiparting line tools.

CAD geometry for Progressive’s new Ejector Accelerators is available from the company’s free parts library — the CADalog — with downloads available in multiple formats, including SolidWorks, NX, VISI, STEP, Parasolid, ACIS and IGES. Individual CAD files can be found at shop.procomps.com.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

.jpg;maxWidth=300;quality=90)