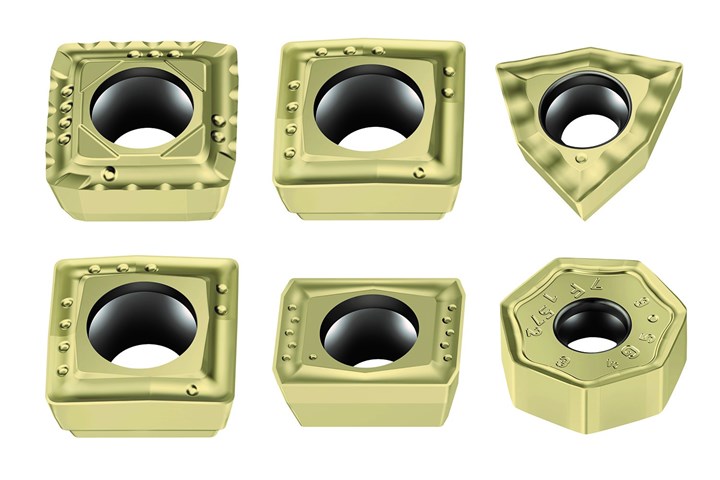

PVD-Grade Insert Reliably Detects Cutting Edge Wear

The Walter Tiger-tec Gold PVD-grade WSP45G insert for milling and drilling operations retains increased wear and temperature resistance for up to up to 75% improvement in performance.

Photo Credit: Walter USA

Tiger-tec Gold PVD-grade WSP45G inserts from Walter USA are wear- and temperature-resistant, more reliable and are applicable to demanding machining tasks such as materials with difficult cutting properties and interrupted cuts. They are compatible with all standard milling cutters in the Walter lineup, including Xtra-tec XT, Walter BLAXX and M4000 milling cutters and can be used for Walter indexable insert drills (e.g., D4120 for ISO P steels) and ISO S and M material groups.

WSP45G is said to boasts a TiAlN-Al2O3 multilayer coating system for improved hardness and toughness. Controlled residual stresses and less flank wear improve tool life. Mechanical post-treatment improves thermal crack resistance and protects the cutting edge from micro-spalling. The light gold-colored topcoat is also said to detect wear, reliably identifying unused cutting edges.

Depending on the material and application, Tiger-tec Gold is able to achieve up to 75% improvement in performance. Automotive, energy and aerospace industries are ideal.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.png;maxWidth=300;quality=90)