Micro-Mold Demonstration Highlights Collaboration

Mold Craft Inc. demonstrates micro-injection molding NPE2018 with a Wittmann Battenfeld press and a Sodick vertical molding machine.

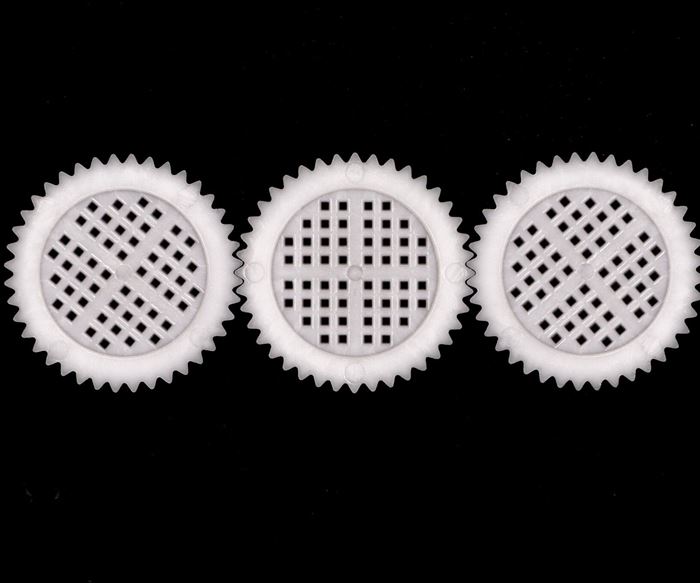

Mold Craft Inc. demonstrates micro-molding of a 100-µm filter screen with POK resin using the Wittmann Battenfeld MicroPower 15-t press in booth W4207. Mold Craft also has personnel in Sodick’s booth (W782), where it molds PEEK 100-µm filter screen micro-parts in the LP20VRE vertical molding machine, which has a two-stage plunger system.

Mold Craft has a typeable .pdf checklist for DFM criteria available at NPE2018 to help visitors describe their perfect micro-mold. If visitors return the completed document, Mold Craft responds with information and advice on moldability and manufacturing. Its complete design package includes models, assembly views, bill of materials and prints with fully documented dimensions and tolerances for the micro-mold.

Mold Craft realizes that certain areas of a mold are going to wear faster than other areas so Mold Craft designs its molds to make those areas replaceable. Those areas include gates, thin steel, shutoffs and core pins. Mold Craft says that it designs molds this way to save customers time and money over the life of the mold.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

-

Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.