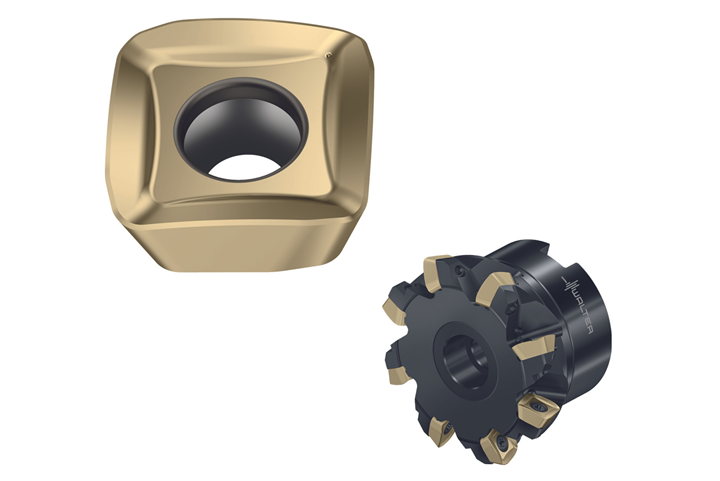

Indexable Insert Reduces Cost, Power Requirements For Demanding Machining Requirements

Walter’s universal system of indexable inserts for the M4002 high-feed milling cutter can machine steel, cast iron, stainless steel and difficult-to-cut materials.

Photo Credit: Walter USA

Walter USA reveals an SDMX indexable insert for its Walter M4002 high-feed milling cutter. Consequential to its highly positive geometries, the square positive, universal insert lowers power requirements. It is thick for maximum process reliability and provides four cutting edges per indexable insert with a curved cutting edge for complete stability.

There are two indexable insert sizes with facet—SDMX0904ZDR-E27 and SDMX1205ZDR-E27. The M4002 cutter provides a depth of cut of 1.5 or 2.0 mm and is available in diameters of 25-125 mm or 1-4" and is ideal for high-speed milling in steel, cast iron, stainless steel and materials with difficult cutting properties. Demanding machining in mold and die making and general machining are also applicable uses.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)