High-Grade, Ultra-Fine Grained Steel Attained Via Novel Heat Treatment

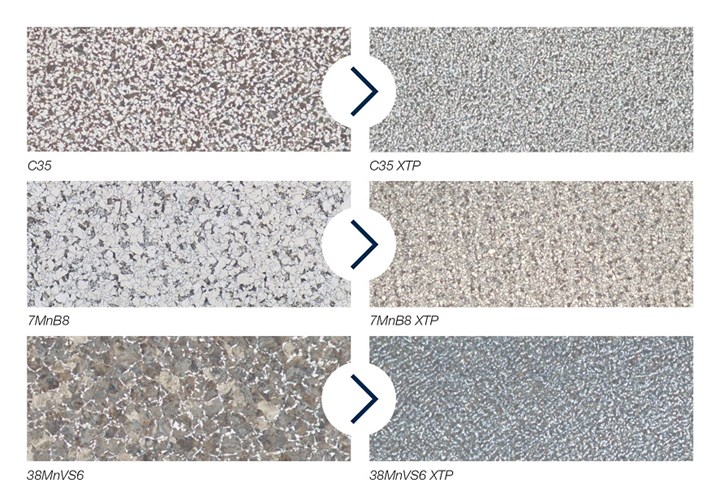

Swiss Steel Group applies its Extreme Performance Technology (XTP) treatment to steels for enhanced dynamic and mechanical characteristics.

Swiss Steel Group announces that it is producing the steel of the future at its Steeltec AG mill. Via Swiss Steel’s “Extreme Performance Technology (XTP),” the company has found a way to produce an ultra-fine grained and tough high-grade steel which makes the need for additional alloys and special treatment obsolete thanks to a controlled thermomechanical processing phase.

Systematic temperature control and alternative forming processes produce an ultra-fine grained steel microstructure with grain sizes of less than 5 µm. Specifically, when subjecting steel to induction heating, Swiss Steel Group uses austenitization to determine material properties and grain size of the steel microstructure. The steel bar is then immediately cooled to the desired forming temperature and fed into the high-reduction roller unit. Steel produced in this way is noted for improved properties with better dynamic and mechanical characteristics, including:

- Improved tensile strength of up to 2,050 MPa.

- Improved dynamic load capacity by at least 10%, leading to longer service life and higher operational safety.

- Significantly improved properties despite higher tensile strength.

- Formability and machinability.

- Components can be re-dimensioned without losing mechanical-technical properties, making component design more flexible.

- Given the straightness of the bars, lengths of up to 8,000 (-0/+200) mm available with tolerances compliant to DIN EN ISO 286-2 *h11 are possible.

- No thermal distortion and no need for additional heat treatment.

In addition to providing a high level of material resistance and strength to enable versatile designs and unconventional component engineering, XTP-treated steel is said to withstands a range of challenges, such as intense vibration, high internal pressure or extreme cold. Even at ultralow temperatures of -101°C at which conventionally produced steel can become brittle and crack or break, Swiss Steel notes that the technically optimized steel grades have a high toughness (notched bar impact work of well over 27 joule in notched bar impact testing). Treatment with XTP technology ensures high resistance to crack propagation.

Steels suitable for XTP treatment are unalloyed steels, precipitation-hardened ferrite-pearlite steels, Bainitic steels, quenched and tempered steels, tool steels, Austenitic stainless steels, Ferritic stainless steel and high-speed steels.

Related Content

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

-

Three Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

.jpg;maxWidth=300;quality=90)