Guide System Offers Precise Positioning in One System

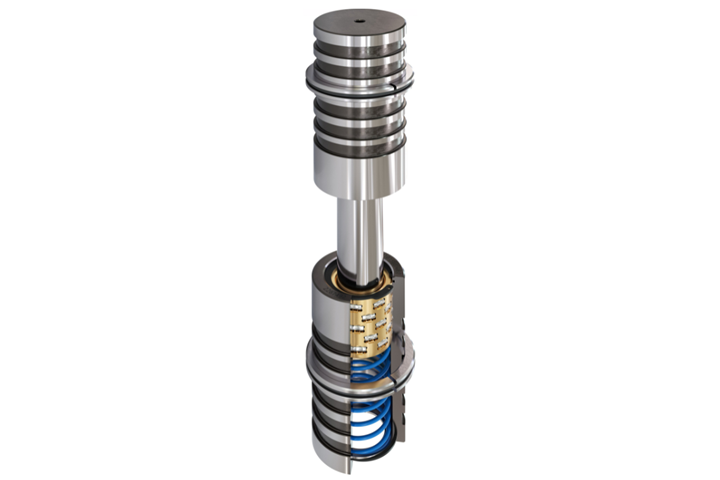

The Agathon Guide System Plus performs guiding and centering tasks for the precise positioning of mold halves/mold components using only one system, increasing planning reliability, boosting productivity and reducing overall production costs.

Share

Agathon Machine Tools continues to highlight its novel Guide System Plus, which performs guiding and centering tasks for the precise positioning of mold halves/mold component using only one system. Ideal for cleanroom, high-precision, micro-injection molding and high-temperature applications, this innovative reinterpretation of existing guiding and centering systems is said to increase planning reliability in production, boost productivity and reduce overall production costs.

By design, each bushing and pillar comes with a freely positioned retaining ring that is adjustable to various plate thicknesses for improved adaptability when repairing or converting tools to newer guide systems. One component can be used in multiple designs.

The guide system bushing is equipped with precision heavy-duty rollers. Agathon says these allow for higher travel speeds compared to conventional slide guides. With minimal line contact by the rollers, serviceable life is said to be increased by 5-12X. The high-precision rollers also provide consistent, accurate movement of mold halves/plates, ensuring alignment, repeatability and consistent part quality.

The Agathon Guide System Plus comes in 15/25/32/40-mm sizes. The company also offers engineering design assistance, to best determine the right system for a user application.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)