Gate Bushing Minimizes Nozzle Component Damage

Thermoplay’s D-bushing component for hot runner nozzles is equipped with a double sealing ring to prevent leaks, protect components and improve insulation.

All photo credit: Thermoplay S.P.A.

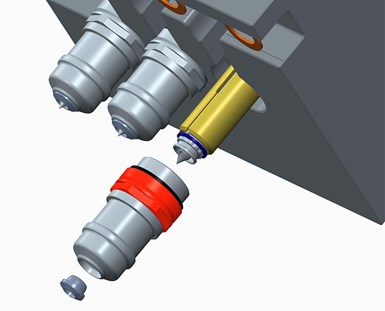

Thermoplay S.P.A. presents its D-bushing component for hot runner nozzles, a solution for high cavitation molds with frequent version changes. Meant to preserve gate point quality and prevent plastics wear in nozzle components, the company’s gate bushing is said to improve safety, stability and reliability during the molding process and consume less energy.

Designed for Thermoplay’s TF nozzles, D-Bushing is equipped with a double sealing ring on the external diameter to protect the injection system—the tips in particular—from thermoplastics leakage, and preserve internal components from wear and potential damage during assembly and disassembly operations, and allows for more frequent changes to the mold version.

The nut is fixed axially to the nozzle bushing. By turning it clockwise, the bushing is pushed toward the nozzle until there is coupling on the sealing diameter of the tip. When the default torque is applied, the bushing is fixed to the nozzle plate. Unscrewing the ring disassembles the bushing. A cable outlet in the middle of the nozzle body allows for replacement of the resistance, thermocouple and tip without disassembling the injection system. Rotating the nut upward or downward when fixing the gate bushing to the nozzle plate and cavity plate does not increase the nozzle’s minimum pitch.

Creating a solid barrier, D-Bushing also increases nozzle insulation for a more homogeneous temperature and reduces thermal dispersion, achieving high thermal performance. For fast installation and maintenance, D-Bush allows for wide layout tolerances and machining of the nozzle seating in the mold.

Related Content

-

CMMs Give Moldmakers Precision, Sustainability, Ergonomic Operation

The new generation of Zeiss Prismo precision measurement devices meet speed, flexibility, sustainability and productivity demands.

-

Large Mold Mounts Eliminate Shop Floor Hazards

Progressive’s new 5-inch-tall RhinoFeet safely supports 15,000 lb each.

-

VIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.