Four-Flute Ball Nose End Mill with Rippled Relief Machines Versatile Material Range

Kennametal introduces a new Harvi I TE Series addition for high productivity and tool life in 3D milling.

Share

Read Next

Kennametal introduces an expansion to the Harvi I TE series, with the addition of a four-flute ball nose end mill. Designed for highly productive 3D roughing and finishing operations—including for mold machining—Kennametal says it delivers low machining cost through maximum metal removal in a broad range of materials.

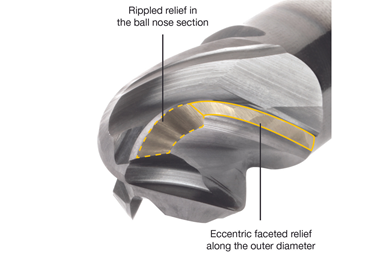

The end mill’s rippled relief enables high feeds and speeds as well as increased depth of cuts by advanced vibration damping and lower cutting forces. The relief changes its shape on the outer diameter, turning into an eccentric faceted relief for exceptional edge strength, geometric accuracy and versatility.

Other geometry advancements in the square end styles —including a twisted end face, chip gashing and a variable helix angle—have also been engineered into this solid carbide end mill.

The Harvi I TE ball nose end mill is available in two different lengths (inch non-necked, metric with neck) both with a diameter range from 2-20 mm (1/16" to 1"). The regular length is the first choice for 3D copy milling operations, while the long version offers sufficient length-of-cut (up to 4sD) for many applications, including shoulder milling when wall and floor finishing is required.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

.png;maxWidth=300;quality=90)