External Fixing Adapts to Plate Control Applications

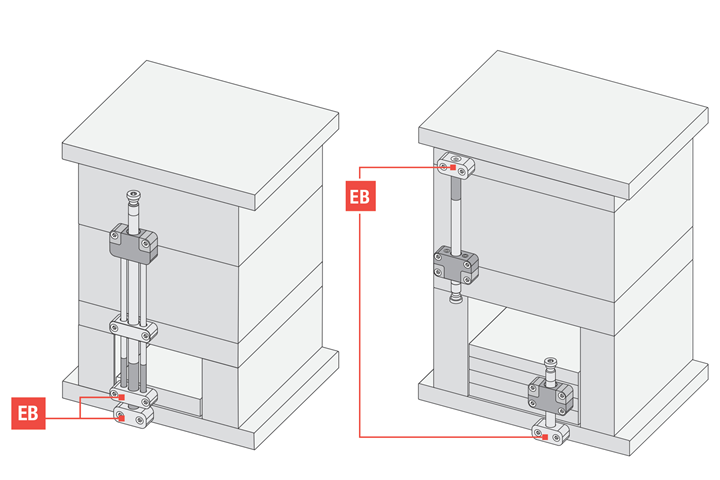

CUMSA’s new adapter (EB) component works with its current line of external ejection systems and offers three different travel choices.

Photo Credit: CUMSA

CUMSA is introducing a new component to work with its current line of external ejection systems, that control the plates during the mold opening and closing sequence. This new product is an adapter (EB), also called an external fixing, which now offers a standard component solution without the need of a homemade adapter.

The external CUMSA systems offer three different travel choices to adapt to many plate control applications including plate pre-openings, two stages or plate control sequencing such as locking selected plates while other plates continue to move.

The external mechanisms, depending on the application, can be attached to the plates as a surface mounting with the new EB solution, or integrated into the plates. It’s currently available in different sizes so it can be used with any of the models of the line, CUMSA says: the EX, EY and EZ.

The adapter holds the end of the rods when the mold is in action. If it is used with the EX and EY models, only one adapter will be needed at the bottom of the central rod. When used with the EZ, two adapters will be needed, one at the bottom of the central rod and one at the bottom of the lateral rods.

The EB is said to be easy to install; further, the need for housing in the plates is eliminated.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.jpg;maxWidth=970;quality=90)