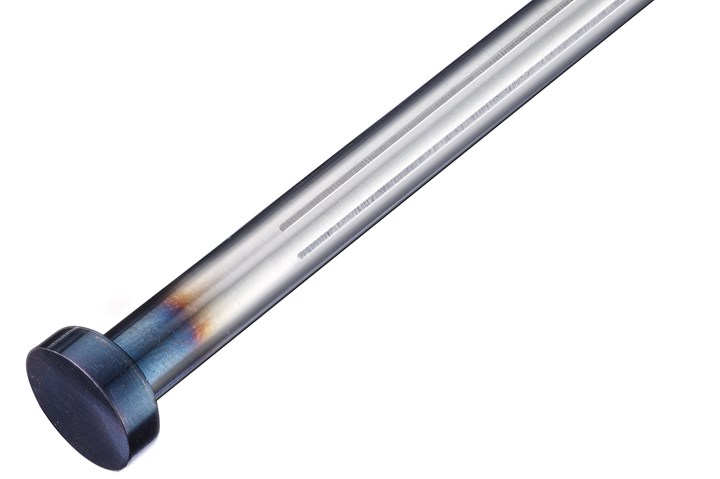

Ejector Pins With Ventilation Surfaces Improve Mold Performance

Hasco America’s newest ejector pins feature extra-long ventilation surfaces so that air can more easily escape cavities within the mold.

Hasco America unveils its new ejector pins Z401 with ventilation surfaces to ensure that the air in the cavity can easily escape, improving mold performance. Specific to this product, the extra-long ventilation surfaces extend over a large part of the ejector pins, so the pins can be easily and individually shortened to the desired length.

During the injection molding process, cavity ventilation must be ensured to help achieve an optimum result when filling with plastic — especially at the end of the flow path, Hasco notes — in addition to preventing the so-called “diesel effect.” Ejector pins provide ventilation via the parting plane of the mold through slides, cores and mold inserts.

The new ejector pins are available in different diameters (1-12 mm) and lengths (100-315 mm, depending on the diameter), and can be interchanged directly with conventional ejectors Z40 or Z41. Overall, Hasco says it is able to comply with customers’ individual requirements, offering maximum flexibility, especially in the field of demolding.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=300;quality=90)