CNC Automation Applications Integrate AGVs, AMRs for Intelligent Control in the Mold Shop

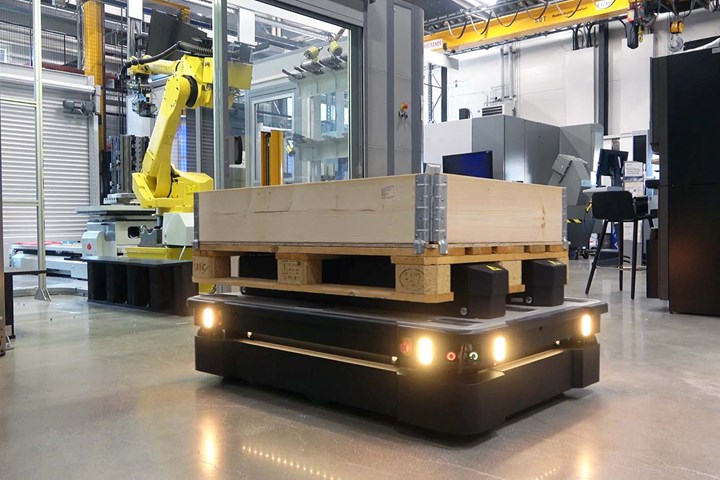

Automated guided vehicles (AGV) or autonomous mobile robots (AMR) incorporating Fastems’ manufacturing management software enables timely, safe and economical transfers of project items.

Within the past few years the number of Fastems’ CNC automation solutions utilizing automated guided vehicles (AGV) or autonomous mobile robots (AMR) has multiplied, and the demand keeps rising, the company reports. Typical AGV applications include material intralogistics, delivering tools to machines and moving machining pallets between production process phases. The common goal of all the AGV projects is timely, safe and economical transfers of production items and Fastems is actively developing ways to use these technologies efficiently with CNC automation.

There are automated vehicles in many production shops, whether it’s in aerospace, defense, machine or mold building. When it comes to CNC automation and AGVs or AMRs, Fastems notes that these solutions can be of great help in reducing manual transfers and forklift operations, reducing buffer sizes, increasing the automation level and making production flow more predictable and reproducible.

Fastems’ manufacturing management software (MMS) is said to bring higher intelligence for AGV use by overseeing all production orders and resources and scheduling everything for timely customer deliveries. In practice, MMS schedules production based on customer orders and available production resources such as machine tools, cutting tools and raw materials, then prompts the AGV’s fleet management software to perform the right transfers at the right time. Moreover, in the event that the unexpected happens — an urgent customer order comes in, or a machine breaks — MMS adjusts the production (including the AGV movement) so that the most urgent jobs still get done in time and all the needed resources are in place when needed.

In addition to customer deliveries, Fastems says it has multiple R&D projects in progress to understand and find the most productive and economical ways of AGV and AMR use in CNC automation. The scope of research involves not only current customer applications but also looks further beyond.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Technology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

.jpg;maxWidth=300;quality=90)