Bar Locks for Optimal Mold, Sequencing Tools Alignment

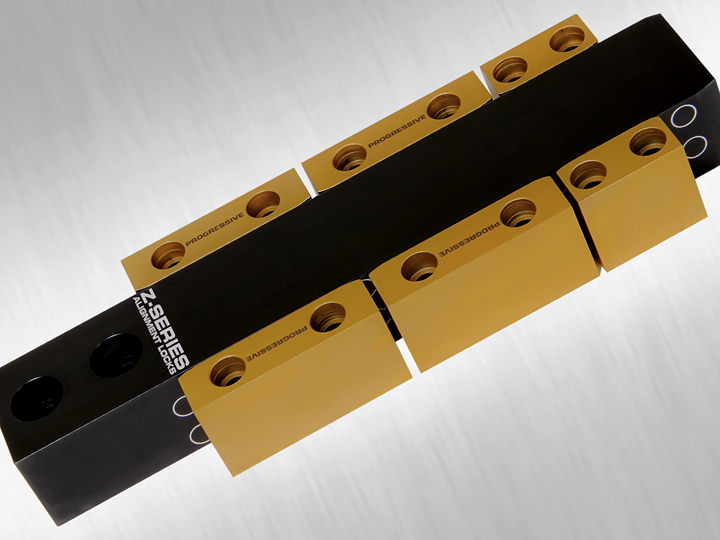

Progressive Component’s off-the-shelf Z-Series patented technology is available in a wide variety of sizes, configurations and plate thicknesses.

Available in a wide variety of sizes and configurations in inch, metric and custom options, Progressive Component’s Z-Series Bar Locks are said to provide perfect alignment of large molds and multi-plate sequencing tools.

“There are a lot of variables in multi-plate tools,” Sebastian Jurczak, project engineer at Progressive, says. “Progressive’s extensive size offering covers the range for standard plate thicknesses.”

Engineered with Progressive’s patented Z-Series technology, Bar Locks are well-suited towards complex molds for packaging and medical applications.

“Others may offer a warranty that their product isn’t defective, but independent testing shows they score and gall after 50,000 cycles,” states Progressive President Glenn Starkey. “Only Progressive offers a warranty for the actual performance longevity so that a mold will close in perfect alignment for the life of the program.”

In addition, with Progressive’s Mold-Ready options, customers can order custom lengths and corner radii for when a lock pocket is not machined through the full plate width. The company sets up fixturing and optimizes the process so that it can ship an altered length with pocket radii, for only the cost of about one shop hour.

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.jpg;maxWidth=300;quality=90)