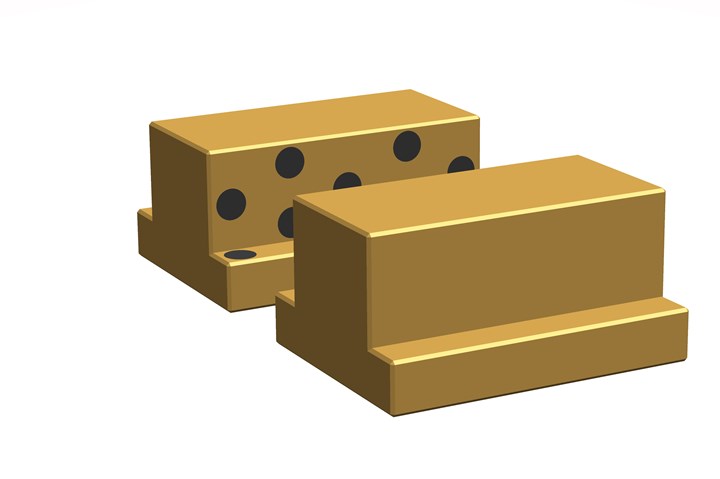

Aluminum Bronze Slide Assembly Component Reduces Maintenance, Improves Tool Reliability

SelfLube’s one-part slide solution designed to run in a T-slot cut in a base plate brings about better alignment, simplifies part exchange, allows faster cycle times.

Photo Credit: SelfLube

SelfLube’s aluminum bronze T-Slides are an upgrade from the steel T-Slides used extensively in slide assemblies. Made in the same dimensions as its steel counterpart, the aluminum bronze component—a one-part slide solution designed to run in a T-slot cut in a base plate—enables a simple swap-out, and, as a less complex part overall, is said to be easier to transition than changing the base.

According to the company, in a typical slide assembly, a steel angle pin is often used to control movement of the T-Slide. However, the use of an aluminum bronze T-Slide neatly eliminates both instances of steel sliding against steel.

Unlike steel, aluminum bronze retains some natural lubricity, a benefit for applications that can tolerate only minimal lubrication. This material also reserves formability characteristics; when parts moving with respect to each other are not precisely aligned along the axis of movement, the part made of aluminum bronze will undergo deformation to bring about better alignment. This ability to deform without damage reduces galling and wear for less maintenance and greater reliability. According to SelfLube, angle pin wear, which is often a problem in high-volume applications, is significantly reduced. Finally, with a more robust configuration, there is potential to operate at higher speeds and reduce cycle time.

SelfLube aluminum bronze T-Slides come in two versions: Plain and Self-Lubricating. Ideal for cleanroom applications, the self-lubricating version uses graphite as solid lubricant, eliminating the need for oil or grease. A variety of custom and standard sizes are available.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)