Westminster Tool Partners with Sumitomo (SHI) Demag to Add Mold Qualification Capacity

Westminster Tool teams up with Sumitomo to add a new 354-ton Sumitomo (SHI) Demag injection molding machine to its Sterling, Connecticut, Technology Center.

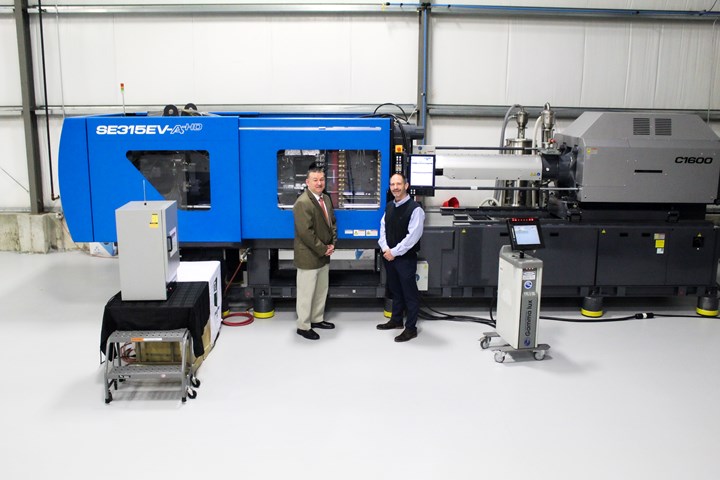

“By partnering with a company like Sumitomo (SHI) Demag, we can rely on their trusted reputation with our customers and validate their molds to their own standards,” says Westminster Tool President Ray Coomb. Photo Credit, all images: Sumitomo (SHI) Demag

Westminster Tool announces that it recently introduced a new Sumitomo (SHI) Demag 354T SE-EV-A-HD injection molding machine to its mold qualification technology center. The new addition will complement the company’s two injection molding presses, a 110-ton and 150-ton.

To expand its mold qualification capabilities, Connecticut-based moldmaker Westminster Tool partnered with Sumitomo (SHI) Demag in hopes of better serving its customers’ needs. Westminster Tool President, Ray Coombs, says the machine’s application will specifically accommodate upcoming medical manufacturing projects that require larger parts and higher cavitation. “Partnering with Sumitomo (SHI) Demag was a natural fit considering the timing, and it’s a perfect alignment of each company’s needs.”

Sumitomo (SHI) Demag, producer of precision plastic injection molding machines, specifically searched for partners that could help it market the machine to a critical regional market in New England. Sumitomo (SHI) Demag North America Business Development Manager, Bob Brady, says, “With Westminster Tool’s reputation in the plastics industry and its reputation in the community here in Connecticut, our machines are getting the exact kind of exposure we need.” He says it was Westminster Tool’s widespread influence as an industry leader, its commitment to skill development and its overall company culture that helped solidify the new partnership.

In addition to mold validation and internal research and development (R&D), the machine’s new home at Westminster Tool will also serve as a centralized showcase for potential training, among both companies and their customers. “Training is a major focal point for Westminster Tool, and that’s why this relationship is such a great fit,” Brady says.

According to Coombs, several of Westminster Tool’s key medical customers are proud Sumitomo (SHI) Demag owners, which makes for a smoother transition from the mold build to qualification. “In the medical industry, it’s all about consistency,” Coombs says. “By partnering with a company like Sumitomo (SHI) Demag, we can rely on their trusted reputation with our customers and validate their molds to their own standards.”

“Several of our features are specifically geared toward the rigid consistency needs of the medical industry,” adds Brady. Features such as Sumitomo’s Zero Molding technology aims to reduce defects to zero by stabilizing molding at a lower mold clamp force, all while maintaining precision and accuracy. And now, with Westminster Tool’s help, the company can demonstrate those features to regional prospects on site.

For Westminster Tool, the new machine represents the company’s latest commitment to merging people and technology. “We spent years establishing our company culture to support our skilled talent,” Coombs says. “Now we need exposure to the technology that is going to allow us to step up our game.”