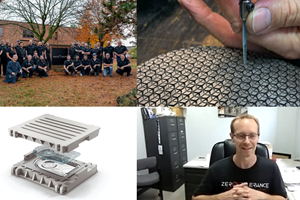

Stratasys, Inc. : RedEye On Demand Named Emerging Manufacturer of the Year

Minnesota Manufacturing Awards Recognize Innovation and Successes in Business

- Years in business (less than 10 years required)

- Percentage increase in revenues, capital investment and total employment from 2010 to 2011.

- Forecasted increase in revenues for next three years

- Programs to attract, retain or train employees

- Efforts to increase productivity and quality

- New services or product development efforts

- Video - Take a Tour of RedEye On Demand

- White Paper: Direct Digital Manufacturing: Impact and Opportunity Part 1 - Freedom to Redesign

- Case Study: RedEye defines museum-quality additive manufacturing in the creation of a life-sized Thomas Jefferson model for the Smithsonian Institute

Copyright © 2012 Surperformance

Related Content

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)