NVision, Inc. Accelerates PPE Production with 3D Laser Scanning

In one recent project, NVision Inc. provided engineering services to a Texas PPE manufacturer, helping accelerate the company’s production of a much-needed protective mask earmarked for medical personnel.

Two recent PPE-related projects completed by NVision, Inc. demonstrate the growing role that non-contact scanning/measurement technologies are taking to create new products and designs to minimize COVID-19 exposure.

In one recent project, NVision provided engineering services to a Texas PPE manufacturer, helping accelerate the company’s production of a much-needed protective mask earmarked for medical personnel. NVision engineers 3D-scanned plaster models of the mask, using the resulting data to create a CAD file which was used to build the special tooling necessary for production.

NVision was contacted by a PPE manufacturer that needed a CAD model of a protective mask in three days in order to start creating the tooling for mass production. The company had only handmade plaster models of the mask; no previous computer models or designs existed.

The mask will be made of vacuum-formed plastic and consists of two parts--an inner and an outer part--with replaceable filter material. SolidWorks CAD models were required to facilitate the machining of suitable dies/molds, as the vacuum-forming process requires dies made from a more durable material, often wood or a metal.

After receiving the plaster models, NVision technicians quickly set to work using the company’s HandHeld laser scanner to collect data on the mask’s surface geometry and dimensions.

The HandHeld scanner is a powerful portable scanning device capable of capturing 3D geometry from objects of almost any size or shape. The scanner is attached to a mechanical arm that moves about the object, allowing the user to capture data rapidly with a high degree of resolution and accuracy. As the object is inspected, the scanner generates a point cloud consisting of millions of points, each with x,y,z coordinates and i,j,k vectors. These points comprise an exact duplicate of the object’s surface, down to the most minute detail. The scanner comes with integrated software that is used to convert the point cloud to an STL polygon and an optional tripod provides complete portability in the field. Intuitive software allows real-time rendering, full model editing, polygon reduction, and data output to all standard 3D packages.

The scanning of the mask models took only two hours, after which NVision technicians converted the STL file to a native parametric SolidWorks CAD format from which tooling could be produced.

NVision engineers provided the mask manufacturer with a CAD model from which it could build the tooling to begin production and meet its deadline for delivery of the masks.

In another project, NVision was asked to scan a series of credit card readers in order to create seamlessly fitting safety covers to prevent transmission of viruses. The covers needed to fit tightly on the readers, so it was essential to obtain the exact measurements of the readers. NVision again used its HandHeld scanner to obtain the precise measurements of the readers, first converting the point cloud to a raw STL file, then importing the file into specialized modeling software and processing the data to an IGES/STEP model, and then further processing to a native SolidWorks CAD model with full feature tree. From that point, client engineers were able to use the CAD model to create tooling for manufacturing the covers.

Related Content

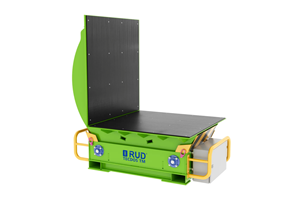

Mold Racks Offer Safe, Practical Access and Storage Solutions

PCS Company’s Mold Storage Racks enable shop personnel to work safely and efficiently, while also providing support and protection for molds, dies and other equipment.

Read MoreCertified Quality Management for Plastics Professionals – Materials to Tooling to Recycling

Why is certification of a shop’s quality management system to ISO 9001, AS9100, IATF 16949 or ISO 13485 so special? What does the certification signify? And what supports the paper behind the framed certificate?

Read MoreIndustrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

Read MoreCMMs Give Moldmakers Precision, Sustainability, Ergonomic Operation

The new generation of Zeiss Prismo precision measurement devices meet speed, flexibility, sustainability and productivity demands.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More