Nexa3D, Addifab Partner on 3D-Printed Injection Molding Platform

The platform, Freeform Injection Molding, reportedly enables users to additively manufacture complex injection mold tooling in hours instead of weeks or months.

Nexa3D, a leading U.S. manufacturer of high-performance 3D printers for industrial applications, and 3D-printed tooling pioneer Addifab are joining forces to bring a novel 3D-printed injection mold tooling platform to injection molders globally.

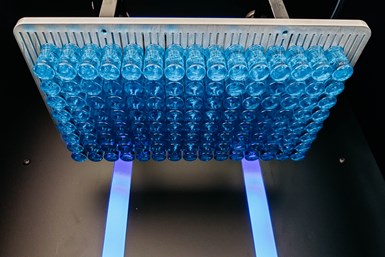

The platform, Freeform Injection Molding (FIM), is said to enable users to additively manufacture complex injection mold tooling in hours instead of weeks or months. These tools are reportedly compatible with most thermoplastic materials, including reinforced high-performance feedstocks. They can also be dissolved, which enables the molding of complex components that would otherwise be difficult to mold with conventional metal tooling.

Through this collaboration, Nexa3D will supply its NXE 400 system, including the industrial 3D printer as well as wash and cure units, to users of FIM, while Addifab will supply its proprietary tooling resins and post-processing equipment.

Avi Reichental, co-founder, chairman and CEO of Nexa3D, explains, “As both Addifab and Nexa3D have since productized and industrialized our respective processes, it became obvious that together, we can achieve much more by digitizing injection molding at convincing scale sustainably.”

Nexa3D and Addifab will showcase FIM at the RAPID + TCT show in Detroit, Michigan, from May 17-19, 2022. The companies are also setting up joint Silicon Valley demo facilities in Palo Alto, California.

The Freeform Injection Molding capabilities, powered by the NXE 400 systems, are available now. For additional details, visit Nexa3D and Addifab’s collaborative package page.

Related Content

-

How to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.