Mazak Canada Event Supports Manufacturing Growth in Multiple Industries

Event connects manufacturers to industry experts and the latest productivity-improving technology for aerospace, automotive, energy and job shop manufacturing.

Mazak will host a special Discover More With Mazak event at its Canadian Headquarters and Technology Centre in Cambridge, Ontario on May 30 from 10 a.m. to 8 p.m. With a focus on aerospace, automotive, energy and job shop manufacturing, the event will pair expert guidance with advanced machine tool technology to help manufacturers maximize their productivity.

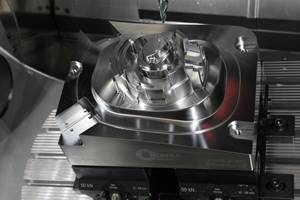

Event guests will experience the world’s most innovative manufacturing technology in action, such as CNC turning centers, milling machines, horizontal and vertical machining centers and Multi-Tasking machines. These machines will demonstrate real-world machining applications and solution ideas for a variety of industries.

Throughout the one-day event, several technology presentations will provide attendees with valuable manufacturing insight. At 11:15 a.m., Sandvik Coromant, a Mazak VIP Partner, will present on its Silent Tools, a family of vibration-dampening tool holders for turning, milling, boring and drilling. Sandvik will demonstrate how these tools supersede those without such capability when it comes to boosting any machine tool’s potential.

Following at 1:15 p.m., Mazak will explore the costs and benefits of various automation processes, with special emphasis on how to best incorporate unmanned operations into a manufacturing facility. Then at 2:15 p.m., Renishaw Canada will present on how manufacturers can use in-process machine tool probing to improve productivity and part quality, while also reducing cost, work in process and delivery times.

Attendees can also take advantage of the Canada Headquarters and Technology Centre’s industry expertise and application engineering resources. Engineers and technicians will be available to discuss all aspects of the manufacturing process, including cutting tools, workholding, automation, material handling, quality assurance, chip handling, coolant, safety and software.

Other Discover More With Mazak – Canada highlights include a programming competition, door prize giveaways and lunch. Event registration information is available at www.mazakusa.com/morecanada.

Also, in conjunction with the event, Mazak is hosting a machining competition, which seeks out the most innovative, complex part made on a Mazak machine in the following categories: aerospace, automotive, oil and gas/mining, and job shop. Four grand-prize winners, one from each category, will be named at the Discover More with Mazak – Canada event and awarded an Apple® iPad® and optional publicity in a major metalworking publication. Plus, every entrant will receive a $100 Home Depot gift card. Mazak owners interested in participating in the competition should pick up an entry form from their sales representative. All entries are due May 22, 2012 and certain restrictions apply.

Technology in Action

Attendees looking to expand their operations through single-setup, Multi-Tasking capability will see the Done-In-One® production power of the INTEGREX i-300, j-200 and i-630V as well as the VARIAXIS i-700. By consolidating machining operations, the Multi-Tasking machines streamline workflow and eliminate set-up errors that often occur when moving components across multiple machines.

To showcase Multi-Tasking, full 5-axis simultaneous machining through high-performance rotary/tilt tables, Mazak will run part-cutting demonstrations of the VARIAXIS 630 Vertical Machining Center. Perfect for the aerospace industry, the machine efficiently and accurately processes workpieces with complex geometries and contours in single part setups.

Perfect for job shops and other high-production environments, the QUICK TURN SMART 250 CNC Turning Center will demonstrate how it effectively fuses technology, productivity and value in a high-performance compact 2-axis turning center machine platform. The machine features a highly rigid integral spindle/motor, programmable tailstock, and automatic tool measuring capability for increasing machining efficiency of a variety of applications from aluminum to heavy-duty cutting of steel.

Regarding automated production systems, event attendees will see the HYPER QUADREX 200MY Turning Center equipped with a gantry robot loader. The dual-turret machine with milling and Y-axis capabilities allows shops to run chuck workpieces in fully unmanned operations. Because the dual turrets can operate independently or together on the same workpiece, the HYPER QUADREX 200MY allows for machining two parts simultaneously or for balanced machining strategies that involve two tools working together on the same part. In cases where the part configuration permits, balanced machining can remove up to 25% of the cycle time.

Attendees seeking to improve versatility and gain unsurpassed value across several applications, ranging from heavy-duty to high-speed machining, will see demonstrations of the VERTICAL CENTER SMART 430A. Featuring a space-saving footprint, this machining center delivers high efficiency machining thanks to a powerful, 40-taper 12,000-rpm spindle and high-speed axis feedrates. The machine also incorporates Mazak’s SMART CNC that maximize ease-of-use and operator efficiency by offering both EIA/ISO programs and conversational programming.

The HORIZONTAL CENTER NEXUS 5000 will demonstrate its high-speed machining capabilities. The Horizontal Machining Center’s advanced headstock design and high-speed, high-accuracy positioning provide unsurpassed part-processing flexibility and significant reductions in non-cut time. The machine’s powerful, 40-taper spindle with a maximum speed of 18,000-rpm utilizes an advanced compact integral spindle/motor, which is designed with low vibration and low heat generation while providing a maximum torque rate of 159 ft-lbs. and spindle acceleration of 1.8 seconds.

Ideal for the aerospace, automotive and energy sectors, the powerful, heavy-duty SLANT TURN NEXUS 550 CNC Turning Center will demonstrate how it efficiently tackles large-part turning applications. The machine employs a headstock with a 275 mm (10.8”) diameter bore mounted on a 60 hp, 1,000-rpm turning spindle that generates up to 5,163 ft-lbs. of torque for high-speed, heavy-duty cutting.

The MEGATURN NEXUS 900 Vertical Turning Center, another great example of heavy-duty machining, will showcase how it excels at cutting large cast iron and steel workpieces. The machine employs a powerful, rigid 40 hp, 1,250-rpm integrated main drive motor/spindle that generates 2,696 ft. lbs. of torque. Additionally, the machine carries maximum part loads of 6,600 lbs. (including the chuck weight).

Related Content

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)