B A Die Mold Inc. Celebrates 55 Years in Moldmaking

Illinois company known for designing and building “bad ass” injection molds proves innovation and love of the industry make a good recipe for success and longevity.

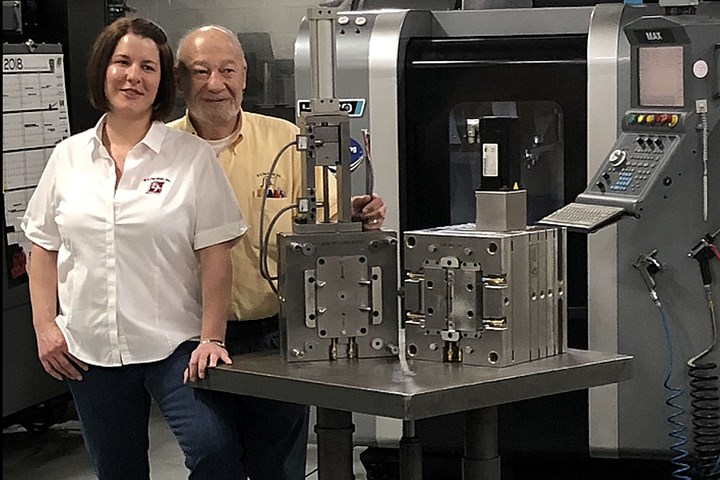

Francine and Alan Petrucci stand in front of the company’s Perc System. Photo Credit: B A Die Mold Inc.

B A Die Mold Inc. is celebrating its 55th anniversary this year. The company, known for its expertise designing and building complex injection molds, in particular the unscrewing variety featuring its patented Perc System, prides itself on having notable longevity at a time when other manufacturers have not been so fortunate.

Many customer testimonials received through the years are enough to provide prospective clients with confidence in B A Die Mold’s capabilities, and yet Alan Petrucci, founder and CEO at B A, is still humbled by the feedback and loyalty customers offer. “I am grateful for our customers, especially those who for many years have relied on B A Die Mold for creativity and excellence in designing and building very complicated molds for medical devices, water filtration and plumbing and more,” he says.

Francine Petrucci, who is Alan’s daughter and president of B A, adds, “B A Die Mold is fortunate to have talented and creative people that work diligently to help customers meet their goals for quality and value with every mold. We love a challenge; and our customers, many of whom we’ve worked with for decades, appreciate our integrity and positive energy!”

She adds that long-time customers also appreciate that B A Die Mold maintains an archive of past jobs and is always willing to service and update molds built many years ago.

Located in Aurora, Illinois, B A Die Mold is looking to grow its team. Visit www.badassmolds.com for more information or call 630-978-4747 to learn more about the company and current opportunities.

Related Content

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

-

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

.jpg;maxWidth=300;quality=90)