Another Solid Gain for Plastics Machinery Shipments in Q2

The industry outperformed other sectors of the U.S. and global economy,according to SPI: The Plastics Industry Trade Association.

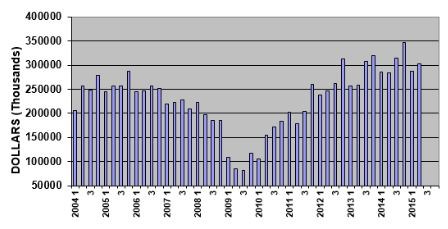

The value of plastics machinery shipped by North American suppliers registered a solid rise in the second quarter of 2015, according to statistics compiled and reported by SPI: The Plastics Industry Trade Association’s Committee on Equipment Statistics (CES).

“The CES shipments data have steadily posted year-over-year gains in every quarter since 2010,” says Bill Wood, the economic analyst who reports on the plastics machinery markets for the CES. “This is a better performance than many other sectors of the U.S. and global economy. U.S. GDP will continue to grow at an annualized pace of at least 2 percent for the remainder of 2015, and the outlook is for accelerating growth in 2016. This bodes well for the plastics machinery markets because it will continue to generate rising aggregate demand.”

Shipments of primary plastics equipment (injection molding, single-screw extrusion, twin-screw extrusion, and blow molding equipment) for reporting companies totaled $303.5 million in Q2. This was an increase of 5.5 percent from the shipments total of $287.7 million in Q1 of 2015, and it was a gain of 6.7 percent when compared with the shipments total from same quarter of a year ago. For the year-to-date, the value of primary plastics equipment shipments is up 3.9 percent over last year.

PRIMARY PLASTICS EQUIPMENT SHIPMENTS

A breakout of the CES data shows that the shipments value of injection molding machinery escalated 3.9 percent in Q2 when compared with same quarter from last year. The shipments value of single-screw extruders slipped 1.5 percent from last year. The value of shipments of twin-screw extruders (includes both co-rotating and counter-rotating machines) eked out a gain of 1.0 percent in Q2. The Q2 shipments value of blow molding machines jumped 66.4 percent.

The CES also compiles data on the auxiliary equipment segment (robotics, temperature control, materials handling, etc.) of the plastics machinery industry. New bookings of auxiliary equipment for reporting companies totaled $121.4 million dollars in Q2. This was a jump of 12.4 percent when compared with the total from Q2 of last year.

The growth in the CES data on plastics machinery shipments was moderately slower than the year-over-year increase of 5.5 percent (seasonally-adjusted, annualized rate) in total business investment in industrial equipment (plastics machinery is a subset of this data) compiled and reported by the Bureau of Economic Analysis as part of their quarterly GDP data release.

The Q2 gain in the CES shipments data was moderately stronger than the other major industrial machinery market indicator, compiled and reported monthly by the Census Bureau, which showed that the total value of shipments of industrial machinery increased by 2.4 percent in Q2 when compared with the year before (plastics machinery shipments are also a subset of this data).

"Despite the volatility in the stock market in recent weeks, the underlying fundamentals indicate that the recovery in the U.S. economy is still intact,” Wood says. “The plastics industry has been a growth leader for the US manufacturing sector throughout the recovery, and this will continue through the foreseeable future. Consumer confidence is rising, residential construction activity is accelerating, and stronger economic growth is expected for the rest of the year. Overall, we are reaping the benefits of low interest rates, low energy prices, and rising household incomes resulting from stronger employment levels. This is more than enough to offset the drag caused by weakness in the oil patch, a stronger dollar, and slower export demand."

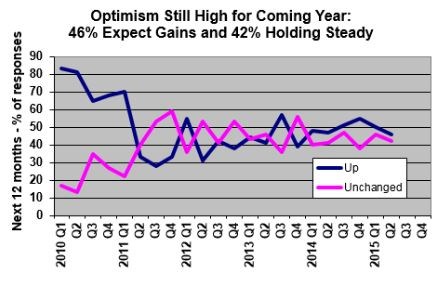

The CES also conducts a quarterly survey of plastics machinery suppliers that asks about present market conditions and expectations for the future. The responses from the Q2 survey indicate that machinery suppliers remain optimistic about the market demand for their products in the coming months. Both in the coming quarter and during the next twelve months, 88 percent of the respondents expect conditions to either improve or hold steady. Quoting activity was higher in the second quarter for half of the survey participants.

North America and Mexico are the global regions where the most promising market conditions for machinery suppliers are expected in the coming year. Expectations for Latin America are for mostly steady market conditions, while the outlook for Europe and Asia are steady-to-weaker.

When asked about their expectations for the major end-markets, the Q2 respondents indicated that automotive and packaging will remain strong in terms of demand for plastics products and equipment. Expectations for all other major end-markets call for firm market conditions to persist during the next 12 months.

For more information from SPI: The Plastics Industry Trade Association, visit plasticsindustry.org.

Related Content

U.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreMoldMaking Conference Session Spotlight: Data

Want to learn about digital workflows in mold design or ERP or global mold monitoring and asset management or the impact of tooling digitalization?

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)