Addifab Raises $6.5 Million in FIM Oversubscribed Funding Round

Funding to strengthen the company’s flagship freeform injection molding process, including its global availability, supply of systems and enable Addifab’s relocation to accommodate FIM’s expansion.

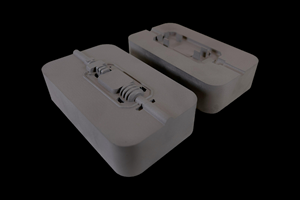

New Addifab headquarters. Photo Credit: Addifab

Addifab (Taastrup, Denmark), developer of freeform injection molding (FIM), has announced that it has raised $6.5 million USD in a recent investment round, which was led by private equity firm West Hill Capital. The funding round was oversubscribed by a factor of two.

AddiFab is transforming injection molding by means of 3D printing. The company flagship FIM process blends qualities from 3D printing and injection molding for fast, low-cost products. The company’s investment round, meant to further accelerate FIM international market expansion, was completed in only 48 hours, and will enable AddiFab to:

- Strengthen global availability of FIM. In 2019, AddiFab teamed up with Mitsubishi Chemical Corp. (Tokoyo, Japan) to offer FIM-as-a-service in the U.S., EU and Japan, and AddiFab is dedicated to further strengthening the presence and momentum of FIM in these and other markets.

- Strengthen communication about impacts delivered by FIM. In the last 18 months, Addifab says FIM has been used to transform the development of products in several demanding industries such as medical devices, PPE, automotive, packaging, consumer electronics, personalized prostheses and critical utility infrastructure. FIM has demonstrated strong capabilities in on-demand low-volume injection molding. Further, the company says FIM is emerging as the gateway to prototyping applications for recycled materials and other materials that are not otherwise 3D printable.

- Strengthen FIM supply of systems. To meet increased demand for FIM, AddiFab has moved to new and more spacious facilities. The goal is to rapidly triple the number of systems that can be produced, while at the same time dramatically increasing the number of customer evaluation projects that can be carried out.

“FIM is quickly gaining acceptance as the number one 3D-printed tooling technology. Superior design freedom and unconstrained selection of materials are key factors driving adoption among injection molders,” says Lasse Staal, CEO and co-founder of AddiFab. “With FIM in their toolbox, molders can reduce injection-molded product times-to-market and costs-to-market, while at the same time raising the bar on innovation, customization and on-demand deliveries. This funding round will enable us to speed up further international roll-out of FIM, to keep up with the increasing demand in the market.”

As a first, highly visible step on this journey, AddiFab has relocated to new, larger facilities. The new headquarters offer more than twice the space for growth. Staal adds: “At AddiFab, we are dedicated to supporting our customers in their implementations of FIM. The new headquarters allow us to take this support to an entirely different level. Whether it be extensive feasibility studies, onsite R&D projects or deliveries of larger FIM system packages, we will be able to accommodate customer ambitions.”

With fresh funding and new headquarters, AddiFab is poised for rapid acceleration as the world moves out from under the shadow of COVID-19.

“The last year has demonstrated the importance of resilient supply chains that are easy to reconfigure and fast to scale up. With FIM, we strike an ideal balance of flexibility and scalability, and we are eager to bring this powerful platform into the hands of even more high-performing teams,” says Staal.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Read MoreHow to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)