Manufacturing Solutions: Wait ‘Til Next Year

As 2010 comes to a close, Americans are still struggling with a high unemployment rate, low consumer confidence, declining house prices and an uncomfortably high level of uncertainty about the future.

As 2010 comes to a close, Americans are still struggling with a high unemployment rate, low consumer confidence, declining house prices and an uncomfortably high level of uncertainty about the future. However to be fair, the manufacturing sector did improve when compared with last year, especially the plastics industry. Total output of plastics products expanded by 7 percent in 2010, and shipments of new plastics machinery jumped by 50 percent through the first three quarters. But we are still far below the output levels we enjoyed prior to the recession, and there is a definite feeling that market demand for molded products is far from hitting on all cylinders.

The next 12 months will certainly be a challenge, but if moldmakers and molders can hold on until this time next year, then the economic fundamentals and market prospects will improve substantially in 2012 and beyond. Total real GDP growth will be 3 percent in 2011, with slower gains at the beginning and then the expansion will accelerate during the second half. In 2012, real GDP growth will be closer to 5 percent.

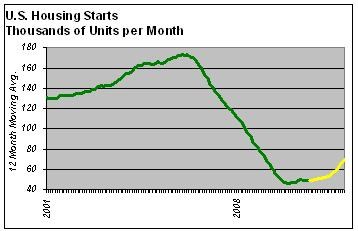

The good news is that we will not have to wait a whole year before we know if this forecast is accurate. The key to righting the U.S. economy is house prices and activity levels in residential construction and real estate. The failure of the housing market is what got us into this mess, and the correction will be the signal that the economy is back on track. Data on foreclosure sales, housing prices and construction activity are compiled and reported monthly, so if trends in these data start to rise then we should take heart.

The foreclosure sales data are particularly important in the coming months because foreclosures are weighing heavily on house prices. House prices are important to the overall economy for three reasons: (1) The wealth effect. About two-thirds of all Americans own their house, and for many of them, their house is their largest asset. When the value of houses declines consumers tend to spend less because they feel less wealthy; (2) When house prices are declining banks are less willing to lend money to small business owners who are offering their houses as collateral; and, (3) Many types of local governments are financed by property taxes, and when house prices decline, tax revenue is diminished. When combined, local governments are the country’s largest employer, and when tax revenues decline then teachers, police, road crews and public works employees lose their jobs. So, this economy does not work very well when house prices are declining, or even when there is uncertainty about whether they will fall.

The good news is that the foreclosure mess is gradually getting cleaned up, and after another year or so, house values will start to appreciate slowly in the vast majority of American markets. Until then, the manufacturing sector will continue to be a driver of economic growth in this country. As I have said before, our manufacturing sector will prove to be the primary hope for long-term salvation for the resumption of the American Dream. In the coming months, I will use this column to offer some new, and perhaps controversial, ideas and solutions for promoting and re-building our manufacturing dominance. I personally can’t wait ‘til next year … so I will start next month.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)