Workshop for Warriors: Fighting for Veteran’ Gainful Employment

Instruction is offered by skilled veterans, active-duty service-members and industry experts. Our programs work to ensure long-term independence and integration of veterans into the workforce.

Workshop for Warriors (WfW), a San Diego-based non-profit organization, has a single mission: to provide veterans of the U.S. Armed Services with vocational training, commercially viable work experience, job placement and an opportunity to contribute to the community. Several manufacturers and suppliers in the industry have donated CNC and waterjet equipment to this worthy cause, which not only helps veterans find secure jobs, but helps to alleviate the skilled-labor gap.

WfW founder and CEO Hernán Luis y Prado says that veterans consistently face significant barriers to employment. “Nationally, the unemployment rate (for veterans) averaged 20.4 percent in 2012—almost double the unemployment rate for the civilian population—and this figure continues to rise,” he says.

CNC machining, welding and waterjet operation are amongst the industry-specific training options available. However, Luis y Prado is quick to point out that the organization also offers mentoring, education and other training to help veterans transition to civilian life. “We provide a combination of classroom education, vocational training and work experience that empowers veterans and increases their career options, confidence and self-respect,” he says. “Instruction is offered by skilled veterans, active-duty service-members and industry experts. Our programs work to ensure long-term independence and integration of veterans into the workforce.”

In order to provide actual work experience and help veterans move from economic insolvency to self-sufficiency, WfW also often organizes hands-on tasks that help disabled and homeless veterans, the community, and local businesses. Recent projects include fabricating handicap railings, handicap-accessible ramps, metal cylinder pallets and new doors for a local restaurant. This teaches the veterans necessary job skills and provides them with a steady income, Luis y Prado says.

Industry Involvement

Luis y Prado urges the mold manufacturing industry to be active in WfW’s efforts. “There are three ways that companies or individuals can help a U.S. veteran who will be a part of America’s new modern manufacturing force: sponsor a veteran with a donation; let your network of friends, family and co-workers know what we are doing; and volunteer your time. We have an ongoing need for people to help at the training facility and in our offices, as well as a need for volunteers who can work from their home for a few hours each week.”

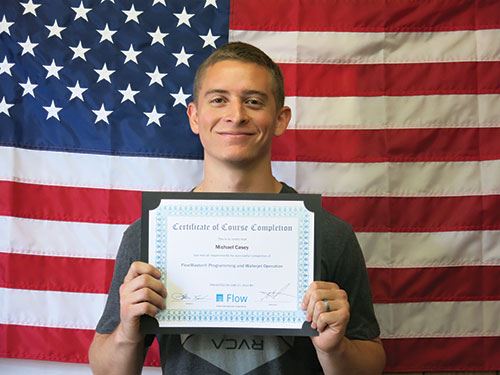

Equipment manufacturers are rising to the occasion with donations as well. Last January, Flow International Corp. provided WfW with a high-speed, high-precision Mach 2c waterjet system with Dynamic Waterjet taper control, HyPlex Prime 55,000-psi pump and FlowMaster Intelligent Control software. Veterans underwent a three-part instructor training program so they could become certified operators on the Flow waterjet system.

Haas Automation Inc. also recently donated four CNC machines to the organization, which enabled WfW to increase its class sizes by 300 percent, and Sandvik Coromant donated $1 for each recycled pound of carbide it received. In addition, the Gene Haas Foundation has offered a matching grant of as much as $100,000 to increase support of veteran training.

WfW already can claim significant achievements. “In the past 12 months, Workshops for Warriors has trained and certified 90 graduates from welding and machining classes,” Luis y Prado says. “The students have already earned 157 certificates, and we have a 100-percent job placement rate with living wages.”

For More Information

Workshop for Warriors / (619) 550-1620

workshopforwarriors.org

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreRead Next

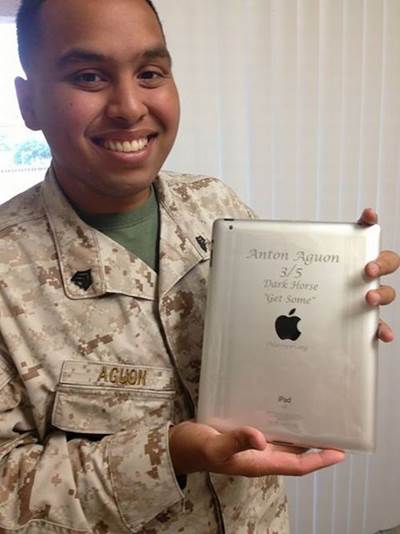

An iWarriors Update: 83 iPads donated so far in 2013!

While many of us have had the opportunity to relax and vacation this summer, let’s not forget that the iWarriors organization continues to put iPads in the hands of our wounded veterans.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)