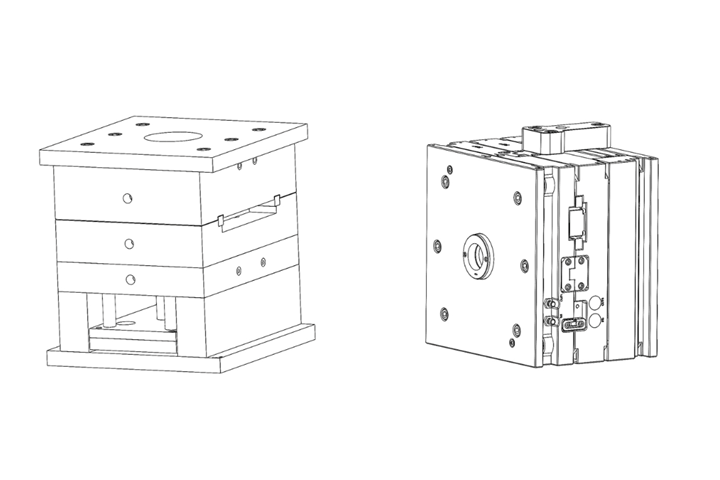

The more people that review a new mold design, the better. At the very least, use a mold design checklist. Photo Credit: Lawrence Mold and Tool

Looking back at more than 45 years of ordering injection molds, I’d estimate I used 40 or 50 different mold builders. On the one hand, that seems like a lot. On the other hand, it’s only about one shop per year. These 40 or 50 mold shops were in at least nine different countries and built over a thousand molds for me, my clients or the companies I worked for at the time. So how do I choose a mold shop? I don’t. The parts do — and occasionally, the customer does.

For example, is the mold for a one-cavity flowerpot, a 128-cavity syringe or something in between? Is the estimated annual volume 1,000 pieces a year, 10,000,000 or somewhere between? The answers matter because the type of part to be molded and the estimated annual production quantity dictate what type of mold builder to use.

There are three goals when selecting a tooling vendor for a project:

- To be awarded the job from the customer.

- To meet the customer’s needs in the hopes of future business.

- To purchase a mold that is not overly expensive but not so cheaply made that it’s a headache on the production floor.

Two critical steps to achieving those three goals are to know whom you are dealing with (or get a referral) and never award a mold to the lowest bidder.

Collaborative Mold Design

To me, the golden rule of mold design is the collaboration among the customer, part designer, moldmaker, molder and anyone impacted by its design and construction, including the often-overlooked need for automation or secondary operations.

However, the key to a successful project isn’t just the mold. It requires a good part design, a good mold design, a good moldmaker and a good processor. If any of these four variables is below par, there’s a good chance there will be a problem.

Proper mold design takes collaboration. A poor mold design is shown on the left and a quality mold design on the right. Photo Credit: Injection Molding Consulting LLC

I sympathize with any molder who receives a mold (new or transferred) and is told to sample it in preparation for immediate production; they usually had no input on the mold’s design or construction. When they can’t mold an acceptable part, things get tense, resulting in production delays and added costs for mold modifications — assuming the mold can be modified to make an acceptable part.

I have less sympathy for molders who outsource their molds — domestic or offshore — but don’t have sufficiently knowledgeable engineering staff or don’t take the time to meticulously review the mold designs before construction.

The type of part to be molded and the estimated annual production quantity dictates what type of moldmaker to use.

If you leave the mold design solely up to the moldmaker, the probability that you will have a problem down the road is exponentially higher. The more people that review a new mold design, the better. At the very least, use a mold design checklist (see Plastics Technology’s August 2021 article, “80 Questions Moldmakers Should Ask Themselves and Their Customers”). Egos should be put aside with the understanding that nobody has a monopoly on experience, logic or brains.

Communication

Let’s discuss how personalities often affect my decision about where to place a mold. My favorite moldmaker is a knowledgeable, straight-shooting professional who communicates well. If a moldmaker doesn’t listen to what I say or builds the mold the way they think is best, that relationship will be short-lived.

Offshore moldmakers are extremely friendly and accommodating. However, sometimes things don’t translate well or they don’t respond to emails when there’s a problem. They only want to give you good news.

Words matter. Here are some examples from my experience:

- A U.S. moldmaker had a booth at NPE about 20 years ago and touted their mold shop in China and the fact that they had American boots on the ground, training and overseeing every mold. I took a chance and gave them a simple eight-cavity cold runner mold that made round parts about the size of a quarter. When we sampled the mold in the U.S., the ejector system bound up after 30 shots and the concentricity of the parts was way off. In the end, we had to rebuild the entire mold. We did not pay the final 30% for the mold and heard that the American company in China soon closed its doors.

- Some shops give you off-the-hip excuses for minor mistakes, which I tolerate only because they make a good mold. One time a moldmaker was three weeks late on the job and the response was, “It’s in the works.” I visited the shop and saw a bunch of plates that were squared up — nothing else. I quickly left with the plates in the back of my truck. Conversely, I got a call from a moldmaker who said he would be late because the inserts were a hair too small after heat treatment, and they sent them out to get plated for a proper fit. I wish that shop, like so many others, were still in business today.

- When a customer asks me why a mold is so expensive, I usually tell them, “I can get a mold for half the price, but I doubt it will make a part you’ll accept or will be able to make parts for very long. Or I can get you a mold for twice the price and you will never have to worry about bad parts or being out of parts. I selected this moldmaker because they suit your product and your requirements best. That’s my job.” Giving the customer a real-world view of the situation is important.

The golden rule of mold design is the joint collaboration of the customer, part designer, mold maker, molder, and anyone else who might be affected by its design and construction.

- The same is true for delivery time. One moldmaker was late on a project I was handling. I confronted them about it and was asked, “Do you want us to cut corners?” That was a clever response.

- My favorite story was when we quoted 18-20 weeks for a mold and the customer said they had a competitive bid from another moldmaker who claimed they could build it in 16-18 weeks. The company president asked if there was a penalty for being late and the customer replied, “No.” The president responded, “Great, we’ll build it in 14-16 weeks.” That didn’t go over well at first. The president then explained that he was very knowledgeable about the industry, knew the mold couldn’t be built that fast, and that his lead time was more realistic. The customer respected his honesty and awarded us the job.

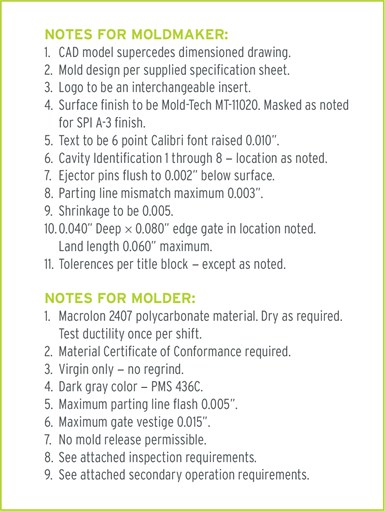

A checklist of considerations for moldmakers and molders. Photo Credit: Injection Molding Consulting LLC

Advice to the Mold Builder and Mold Buyer

The ultimate goal of this partnership is to make money on the project by obtaining a mold that meets everyone’s needs for the project’s lifespan without being overly expensive. This goal takes the right partnership.

To the mold buyer: Have a list of at least 10 mold builders with various levels of precision with whom you have experience. Mold builders who know your preferred brand of steel, mold components, locating rings, hot runner systems, etc. You must establish a relationship with the moldmaker and overcome a mutual learning curve. Once you have your list, selecting which one gets the job becomes straightforward. However, things do change over time.

For example, governments put tariffs on molds from various countries (currently 25% in the U.S. for Chinese molds, on top of the 3.2% duty). In the 1970s, my father purchased almost all of his molds from Portugal. The quality was good and the exchange rate was very favorable. I purchased some molds from Taiwan before China became a more significant player. You need to have a global perspective to stay competitive in this marketplace.

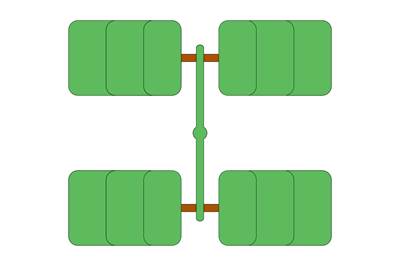

If you think China is a threat to the U.S. moldmaking industry now, I guess it will only worsen. Their lead times are quoted in days — not weeks. They give you a design for manufacturing and a flow analysis at no additional cost. Somehow, they can design a mold in just a few days. The last mold I placed in China was an eight-cavity cold runner. When I saw the mold design, it had a Beaumont-type Melt Flipper runner system! Their government-subsidized equipment is state-of-the-art and they seem to absorb information like a sponge. On the flip side, I know a few domestic moldmakers who love Chinese molds because they make a very good living fixing their shortcomings.

There are expected and unexpected risks when buying an injection mold. For example, you find a good offshore mold builder, the sample parts look great and the customer’s excited to get into production, but then the cargo container holding the mold falls off the boat into the rough seas. You should ask your insurance agent if you’re covered for freak but expensive incidents like flood, fire, loss or damage in transit.

The key to a successful project isn’t just the mold. It requires a good part design, a good mold design, a good moldmaker and a good processor. If any of these four variables is below par, there’s a good chance there’s going to be a problem.

To the moldmaker: Get to know your customer. I never cared if they were friendly or not. I only cared if they were knowledgeable about molds and molding. A smart customer will give you a 2D drawing as well as a solid CAD model. The 2D drawing typically specifies the material type, preferred gate and ejector pin locations, surface finish, etc. like those shown in the “notes” image above. If your customer is not experienced with molds and molding, pull the information out of them using a checklist to ensure you don’t miss anything.

Also, when you quote molds, review part designs closely and make recommendations for improvement, especially if a part will be used in an assembly. I estimate more than 60% of the part designs I’ve reviewed over my career were missing draft in some areas, required radii on inside corners or needed to be cored out more. Reviewing the part design is more for your benefit than the customer’s because you won’t get repeat business if your mold makes a part exactly like their model, but can’t be molded without shorts, sink marks, warp or other rejectable issues.

Today’s moldmaker must be an industry expert with a strong focus on collaboration and communication to secure new business or land another job from an existing customer.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

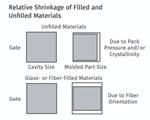

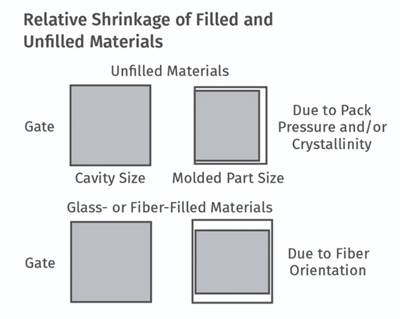

Read MoreBest Practices for Hitting Critical Numbers: Communication and the Shrinkage Factor

Start with an upfront review, discussion and collaboration with the customer and then consider the shrinkage factor.

Read MoreSave Time, Money: Use a Mold Design Checklist

Here are 15 examples of common molding issues that occur during an initial mold trial. Many of them could be avoided or corrected with a proactive checklist.

Read More

.jpg;maxWidth=970;quality=90)