WEBINAR RECAP: 2020 Insights into Automotive Business Activity

Forming strategic partnerships that help “mobility” manufactures build their vision for the future are key to taking advantage of new business opportunities.

Share

Read Next

“The automotive market is shifting, and the numbers and types of participants are exploding,” Michael Guckes, chief economist and director of analytics for Gardner Intelligence, the parent company of MoldMaking Technology, says. So, two main questions to ask yourself are:

- Will you be able to support this complementary industry to the traditional automotive marketplace?

- How quickly can YOU provide solutions to what tomorrow’s manufacturers (not your traditional automotive car maker) need?

A few takeaways from Guckes and Gary Vasilash, editor of Autobeat include:

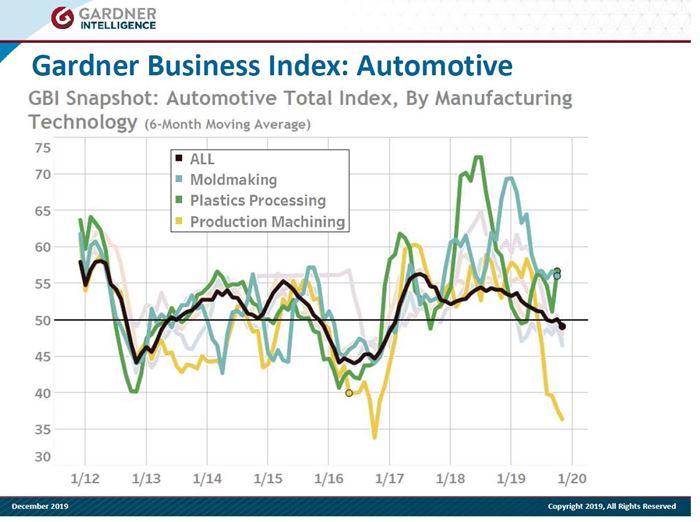

- Gardner Business Index data taken from U.S. survey participants:

- Acceleration of automotive activity in the Southeast

- Moldmaking continues to do well

- Profit margins for auto parts makes are 2% greater than the OEMS.

- 2-year revenue growth projections by Wall Street analysts for the supply side manufacturers are DOUBLE that of the OEMS.

- Auto parts manufacturers are spending money on capital expenditures

- Dominance of SUVs and light trucks in the U.S.

- Investment in autonomous vehicles is growing

- Traditional OEMs looking for their stocks to be valued as Silicon Valley companies are

- Shift from car manufacturers to mobility suppliers

- For example, Toyota developed an autonomous shuttle vehicle for the 2020 Tokyo Olympics

- Fleets as opposed to personal vehicle due to cost of sensors and processors.

- Five-years shift in vehicle supply such as robotaxis will help manufacturer determine what companies to work with

- How a manufacturer partners will be of great importance.

- Will allow those who are not strong in automotive to come into market through a back door. For example, instead of working directly with Toyota work through Uber

- Strategic partnerships will continue to multiply, providing multiple “front doors” to knock on

- Tesla has 77% of the market allowing them to introduce the cyber truck

- Skateboard platform on which to build any vehicle

- Ford’s Mustang MACH-E is an electric utility vehicle to capture that market

- Hyundai is a manufacturer to watch. For example, its Concept Semi H2 truck

- Mild contraction in automotive sales in the EU

- The truth about China’s economy is that it is down, as per China Association of Automobile Manufacturers, and Chinese sales and production is experiencing a slump

What does it all mean? Guckes and Vasilash share the following:

First, break the mindset that to get into automotive you need your sales guys to call Ford, GM, FCA and all the other traditional OEMs.

Tons of non-traditional firms are getting in this space. If your sales guys can’t break through with an OEM look widely elsewhere; get creative.

For example, a moldmaker who is going to wait until all the dust settles in a few years to start supplying necessary technologies is not going to have the first-mover advantage. Today is the time for mold builders and molders to place their bets, build relationships with one (preferably several) firms that are building out the technologies for tomorrow’s cars.

All vehicles are going to move towards greater use of plastics, composites and other lightweight products.

This move is because of increased use of electronics in vehicles. Consider the sensors and infotainment systems in today’s EVs. This also applies to non-EVs. Consider the 2021 Suburban and more typical drivetrain cars, we are moving towards movie theaters on wheels, tons of plastic inside and outside the vehicle!

Light weighting will be integral to building vehicles that can go today’s travel distances and meet emission requirements.

Automation will put us closer to mobility as a service.

Expect robo taxis to have a huge amount of miles put on them in a short period of time. The vehicles have to be made more durable, forcing the increased use of composites, plastics etc.

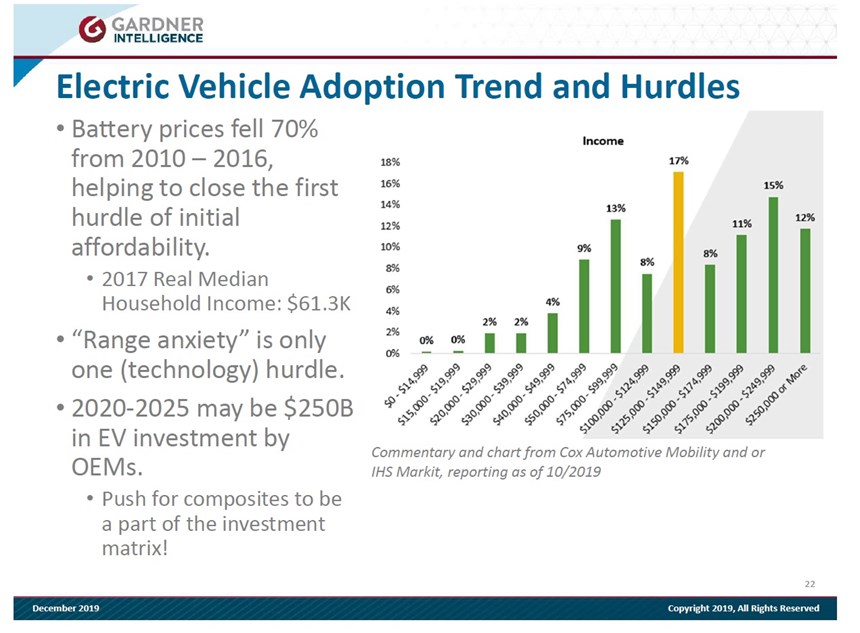

The downside is that automation is too expensive for 80% of the market. Most EV buyers make over $125K today, only about 30% of EV sales come from people making at or below $100K.

How will plastics and other material manufacturing play a role in getting costs down?

Click here to hear the entire webinar for FREE.

Related Content

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreMMT Chats: Giving Back by Answering the Moldmaking Education Need

MoldMaking Technology Editorial Director Christina Fuges checks in with Bruce Cateon, an executive advisor at OASIC Consulting. Bruce started out in moldmaking, eventually becoming an industry consultant and taking time to work on his passion project the “Injection Mold Design Handbook” as a way of giving back to the industry that has given him so much. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More