Tradeshow Tuesday: a New Blog for a New Year

2018 has finally arrived. One new thing for MoldMaking Technology is a new topic for the Tuesday blog. Through August 2018, some of the Tuesday blogs will cover issues related to tradeshows.

Happy new year, everyone! As I’m typing this, it’s a balmy 15°F outside. Tis the season for hauling away holiday decorations, shoveling snow, making (and maybe breaking) new year’s resolutions and welcoming new things. 2018 has finally arrived. One new thing for MoldMaking Technology is a new topic for the Tuesday blog. Through August 2018, some of the Tuesday blogs will cover issues related to tradeshows. Now, if you are a big fan of the slideshow blogs, don’t worry! It is likely that those will be a part of this focus.

Through August 2018, some of the Tuesday blogs will cover issues related to tradeshows.

To most of you, it probably sounds like a broken record when you read, for the umpteenth time, about all the exciting events taking place this year. Still, just in case you have been living under a rock (and let’s be honest, we’ve all been there), you just returned from a special space expedition to infinity and beyond, or you are brand new to moldmaking and tradeshows, 2018 is a major year for the moldmaking industry!

MoldMaking Technology Editor in Chief Christina Fuges highlights the wonderful events and milestones taking place in 2018 in her editor’s note for January. MoldMaking Technology magazine celebrates its 20th anniversary, and Modern Machine Shop celebrates its 90th anniversary in 2018. Additionally, the NPE tradeshow from the Plastics Industry Association, Amerimold and the International Manufacturing Technology Show (IMTS) are all taking place in 2018.

One theme from the January editor’s note that stands out is opportunity.

One theme from the January editor’s note that stands out is opportunity. With so much going on, it’s all any of us can do just to get through it! But, these events are so full of opportunity that we can’t afford not to fully capitalize on chances for increased publicity and visibility or on prospects for new or increased business. Getting the most out of tradeshows is largely about planning and about having all the information available to make those plans.

Many of you undoubtedly have weathered major tradeshow years in the past, so of course you know what’s coming. Even if you feel like you have been to so many that you can put the whole thing on autopilot, I still encourage you to check out the tradeshow coverage in this blog. MoldMaking Technology will cover topics on things like product submissions, social media on the tradeshow floor and tools like Map Your Show. Some of these things are either routine parts of your tradeshow experience or are things you have never explored or have ever even considered exploring. The goal of this blog is to highlight tips and best practices for getting the most out of the parts of your tradeshow experience that are routine and to give you a run-down on things you might not have checked out in the past.

The goal of this blog is to highlight tips and best practices for getting the most out of your tradeshow experience.

The more you know, the more you can do. I hope you find the material that I cover useful as you get ready for the events ahead. If you have any questions about PR, if you have any questions about products and news for an upcoming show, or if you have any questions about the tradeshow topics in this blog, please reach out to me at kcornelissen@moldmakingtechnology.com.

Interested in more coverage on these shows? Check out the NPE, Amerimold Expo and IMTS zones at MoldMaking Technology online. Get the latest news, articles and columns on each show.

Related Content

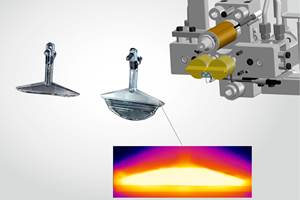

Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read MoreMold Technologies Division of SPE Announces 2024 Award Recipients at NPE 2024

The Mold Technologies Division of the Society of Plastics Engineers (SPE) honored recipients of four awards at NPE, recognizing excellence in moldmaking and supporting the next generation with a new Apprentice of the Year award. Each winner receives a $1,000 stipend for their training program.

Read MorePLASTICS Presents NPE2024 Education Sessions

NPE’s academic program has been redesigned to aid advancement within the plastics industry.

Read MoreNPE 2024 Set to Showcase Solutions for 6 Key Moldmaking Trends

The moldmaking and plastics industries have undergone some changes in the past six years, all of which emphasize the importance of innovation and adaptability for competitiveness.

Read MoreRead Next

2018 Is a Big Year of Events and Opportunities for Moldmakers

A positive projection in growth and spending from Gardner Intelligence is timed with NPE, Amerimold and IMTS, MMT’s 20th anniversary milestone and the 15th anniversary of MMT’s annual Leadtime Leader Awards competition.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)