The Real Cost of Your Cutting Tools

The prime consideration is not how much your tooling costs, but how much it earns.

Moldmakers are concerned about containing operational costs, especially in today’s challenging economic environment. However, there is one area where too narrow a focus on cost-cutting can end up hurting your bottom line. That area is cutting tools.

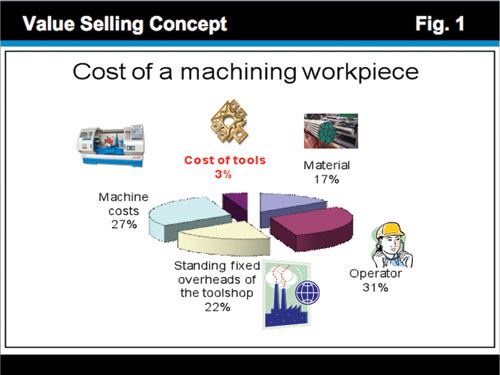

To explain why this is the case, let’s first take a look at the actual costs involved in producing a part in the metalworking industry (see Figure 1). Studies have shown that labor is the prime input, accounting for 31 percent of the total cost. Next comes machinery, which accounts for 27 percent, followed by facility and administration—a catch-all category that includes everything from bookkeeping to keeping the lights on—at 22 percent. Material accounts for 17 percent of the cost.

Finally comes tooling, amounting to a mere 3 percent of the total cost of producing a part. What does this mean to the typical moldmaking shop? Let’s say you secured a whopping price cut of 33 percent in the cost of your tooling. This 33 percent decrease in price would only reduce the total cost per workpiece by 1 percent.

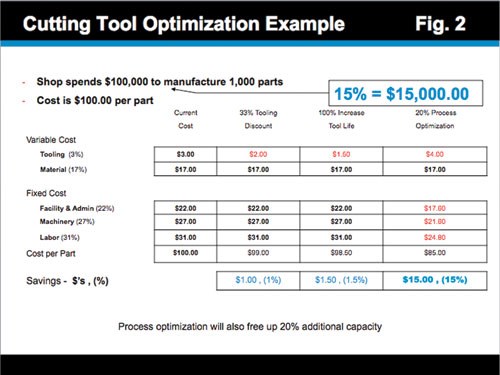

The story is similar with tool life. Along with tool cost, tool life is usually looked upon as a deal clincher, an obvious and incontrovertible indication of what to buy and what not to buy. A closer look at the figures; however, tells a different tale. Since tooling accounts for just 3 percent of the total cost of a part, a 100 percent increase in tool life only reduces total cost per workpiece by 1.5 percent.

Clearly, the cost of one cutting tool insert as compared to another is not particularly relevant. This is not to say that cutting tools can’t have a significant impact on cost. They can; in fact, they can have a dramatic impact on the cost per part, but this impact is manifested in the way that cutting tools affect productivity, and thus the shop’s bottom line.

The lion’s share of the cost of a part is a function of time; that is, the time a part spends on the machine tool, the amount of time the machinist must spend to produce that particular part, and the amount of overhead (e.g., facility and administration) that is allocated to that part on a time-denominated basis. That’s why if you can reduce the time required to produce a part by 20 percent simply by switching to a more efficient cutting tool you can typically reduce your cost per part by as much as 15 percent (see Figure 2). It also frees up 20 percent more machining capacity without any additional capital investment.

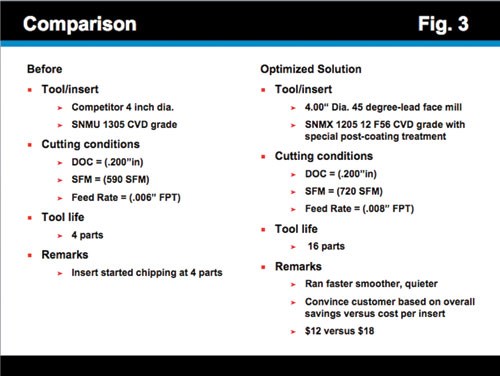

What constitutes a more efficient cutting tool? That of course depends on the type of tool you are currently using and on the application, but there are three factors to look at (see Figure 3).

1. Geometry. Often, the primary factor limiting material removal rate is the horsepower of the machine tool. However, some of the newer high feedrate milling cutter inserts feature a more aggressive geometry allowing for freer cutting. This typically takes the form of a lead angle of around 15 degrees. These newer designs permit faster feeds and greater material removal rates without an increase in horsepower.

Tool geometry can also impact chatter. Chatter is often a systemic problem, with insufficient machine and spindle rigidity a frequent contributor; however, there is no doubt that tool geometry is a major factor. Because of their freer cutting action, these newer tool designs decrease the likelihood of chatter. Though difficult to quantify, this tends to increase both part quality, specifically in the area of surface finish, and tool life as well.

2. Coating. This is an involved subject, one that can easily merit an article of its own. However, we will cut right to the chase and focus on a couple of new developments that could have great significance for moldmakers. First, look for roughing grades featuring newer forms of CVD-Al2O3 coating. When combined with newer forms of post-deposition surface treatment, tools with this coating exhibit superior wear resistance and toughness, as well as increased resistance to thermal cracking. This allows the tools to be run at higher speeds, boosting productivity and netting savings in machine, operator and overhead costs. Also, the greater resistance to thermal cracking increases tool life. This decreases tooling costs and, more importantly, it also decreases machine downtime as the machine doesn’t have to be stopped as often to change out chipped tooling. This can have significant effects on a shop’s bottom line.

3. Support. Application support can be a major source of productivity enhancement for moldmakers, one that is often overlooked. Though advertising and promotional material can be helpful, and tooling company salesmen can typically provide useful information, when considering a tooling purchase these two sources of information are not enough. Moldmakers should contact the cutting tool company’s applications staff. These are the people who should be able to provide you with real-world information relevant to your specific applications. After discussing your needs with an applications professional, you will probably wish to test the product in conjunction with that applications professional. Along with imparting information about tooling, a knowledgeable applications professional can sometimes provide you with valuable insight into your overall production process.

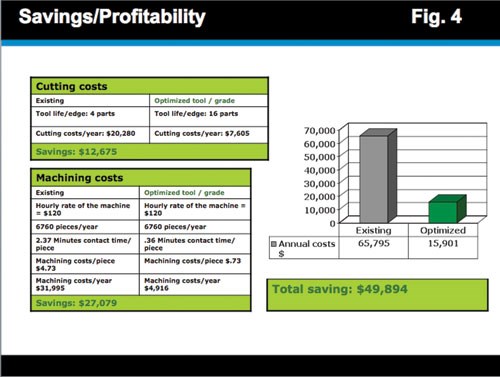

These are some of the ways in which the correct tooling can boost your productivity. An optimized savings/profitability scenario is presented in Figure 4. Regardless of application, the factors discussed all can have a sizeable impact on the bottom line and they all dwarf the cost of the tool itself.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Holders/Cutters/Inserts Combination Maximizes Productivity

A switch in cutting tools triples the output at a die stamping facility.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)