The Myths of Change

More than 40 years have passed since the U.S. government decided to go metric; yet, many in the U.S. moldmaking industry still hang on to the imperial system, leaving some baffled as to how and when we will see a complete conversion. It does not matter what it is we seek to change, a few simple rules apply in our decision process. It is not just a rejection of metric, it is a rejection of any change that these rules apply.

More than 40 years have passed since the U.S. government decided to go metric; yet, many in the U.S. moldmaking industry still hang on to the imperial system, leaving some baffled as to how and when we will see a complete conversion. It does not matter what it is we seek to change, a few simple rules apply in our decision process. It is not just a rejection of metric, it is a rejection of any change that these rules apply.

A myth is that some think a change will never happen unless we see a positive benefit, but that is not entirely true. Even if we see a benefit, we will want to keep on doing the same old thing unless we fear something bad will happen if we don't.

We can never change a habit, we can only replace it with a new one, and we will have to make a conscientious effort over time with the help of another stimulus to keep up the habit we want to replace the old one with. The fact that when we have a habit of thinking in imperial measurement that is in our subconscious mind and locked in the more we use it.

Another point to consider is the only real financial motivation to make the change is for those who only want to sell metric and wish to reduce their inventory selection and get more cost reductions for economy of scale, so prices for metric-sized components will cost less. Once imperial components lose volume and become less available, it starts to become more expensive.

So unless we realize that resistance to change is really nothing but a habit, it makes no difference. The decision to change rests with the culture of the group and the perceived advantage. It just seems like prolonging the inevitable is the mode of action.

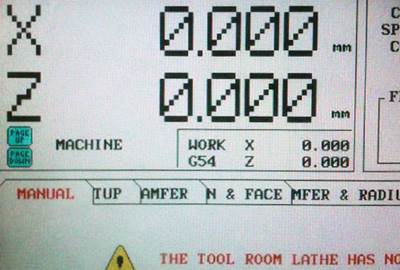

Another variable is globalization, which is linked to offshoring and has been linked to the metric conversion as well—giving those who do not want to change a reason for staying with their habit—e.g., we didn't have calipers that were metric and it was going to cost more to convert; now all instruments are digital, so they can convert to metric with a flip of the switch.

The customer dictates what we use, so now that we are global most of the customers are making metric a requirement. The next excuse is that we cannot get supplies, which is only because we refuse to look for them because it takes too much time.

We need to think about how globalization is a concept that brings with it all kinds of dilemmas, and when used correctly, can help us make a better world. The unfortunate part is our fear of change. These fears were elevated as things went offshore, but now as things are coming back we have a chance to get our business community back in order— standard measure and simplification.

Check out MMT's April article, Think Metric, Part 2

About Our Guest Blogger

David Outlaw is with Outlaw Seminar & consulting service, which is based on his personal experiences of how we solved some of the dilemmas most entrepreneurs have when developing a new package for their product. It is mixed with organizational concepts used in managing injection molding, moldmaking and product development and all the technical information used in our industry.

Outlaw Seminar & Consulting

(727) 480-7255

info@outlawsolutionsandconcepts.com

outlawsolutionsandconcepts.com

Image courtesy of FREEIMAGES.co.uk

Read Next

Think Metric

One man builds an argument for designing and building in metric. Part 1

Read MoreThink Metric: It’s All in the Numbers, Part 2

Feedback from the field on making the metric conversion in your shop after realizing it just makes sense.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More