Testing the Waters With Multi-Material Molding

This shop’s sampling capabilities enable customers to take a step-by-step approach to these applications without the risk and expense of purchasing a dedicated press.

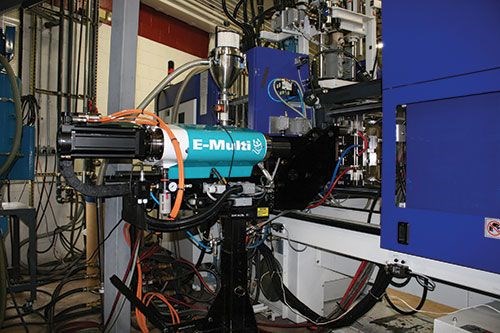

Capability to mount horizontally to the mold enables E-Multi users to mimic a wide variety of injection press configurations.

About three years ago, one of Accede Mold & Tool’s long-time customers asked for guidance on producing multi-material parts for an OEM further up the supply chain. The customer had only single-shot presses, and although it was interested in adding multi-material capability, it couldn’t justify the expense. After consulting with Accede, the customer realized it wouldn’t have to.

Thanks to an auxiliary plastic injection unit that fits vertically or horizontally onto any standard press, Accede was able to develop a process to produce the part using the customer’s existing equipment. In a scenario that’s since been repeated many times over, the customer is still using that process—and that unit, an E-Multi system from Mold-Masters—to this very day. Read this case study to learn more about the unit’s effect on Accede’s sampling and validation operation.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

.jpg;maxWidth=300;quality=90)