Tech Molded Plastics Helps Students Make a Career Connection

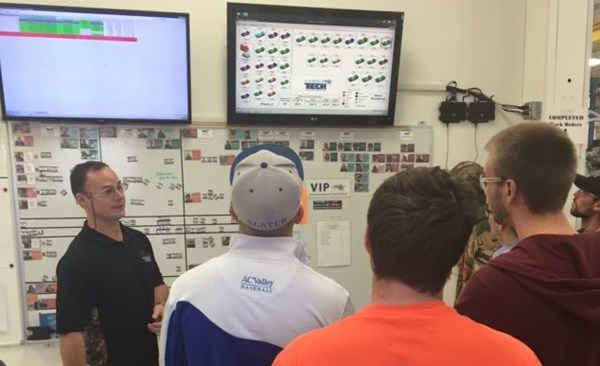

Tech Molded Plastics gave 19 Technology Leadership students from Clarion University of Pennsylvania's Applied Technology Program an inside look at advanced manufacturing.

How often do students get an inside look at advanced technology as it applies to their future career? Not often enough, according to Clarion University and Tech Molded Plastics, a Meadville, PA-based company specializing in high performance molding of engineered resins for complex applications. The two organizations recognized the need to show students how their studies apply to real-world opportunities. The result was an interactive experience that took 19 students inside the process of molding precision plastics, problem solving and topics essential to job satisfaction.

During the event students had an opportunity to talk directly with skilled technicians as they performed their jobs on some of the most advanced precision manufacturing technology in the industry. Beyond machines and equipment, they experienced the integration of quality systems, procedures, work instructions, leadership skills, communication tools and information technology required to maintain competitive advantage. Additionally, Stereotypes were shattered in the feedback session with comments on an extremely clean, white-room environment organized methodically with automation, smiling people, computers at every work-cell and career opportunities for most all skills.

"When you read about the application of robotics working hand-in-hand with conveying systems and skilled people, you don't see the art and craftsmanship of the men and women that make it all happen," stated Tech's VP of Facilities Doug Hanaway. The interactive experience laid out the path where business development engineers, marketing specialists, accountants, human resources, quality technicians and other skilled people work as a team to make the products that are taken for granted every day.

Clarion University's Applied Technology Program Director & Instructor, Tim Taylor, shared, "It isn't very often that an owner of a company takes the time to conduct the tour themselves. It made a positive and permanent impression on my students! Everyone that either I or my students spoke with thoroughly answered questions and described their job duties in detail. Everyone seemed more than happy to share with the students and the positive vibe was everywhere!"

Learn more about Tech Molded Plastics at: www.ttmp.com.