Take a Break and Listen In

MMT has covered how the right mold components can help improve mold cooling and produce higher-quality parts, but this week we had two experts speak about the fundamentals of mold cooling and components for optimized system design. The recorded webinar is now available.

MMT has covered how the right mold components can help improve mold cooling and produce higher-quality parts, but yesterday we had some experts do a webinar on the fundamentals of mold cooling and components for optimized system design. The recorded webinar is now available for viewing.

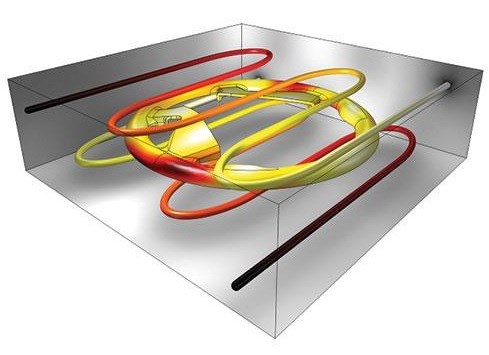

Historically, mold cooling was designed to circulate water or a cooling medium through the mold base plates and not necessarily within the cavity or core inserts. This usually requires many different levels of cooling lines and thicker mold plate assemblies. This webinar discussed newer advancements that create a circulation that is now optimized within mold plates and specialized within the cavities and cores to reduce mold heights.