Steel Heat Treating

The third in a series of articles on heat treatment, this month's offering looks at the heat treatment procedure, its principles and why heat treatment is necessary for steel.

Continuing with the series of tutorial articles on the subject of heat treatment, the next step is to look at the basic heat treatment procedure, its principles and why it is necessary to heat treat the steel. The previous articles have reviewed "What is Steel" and the "Influence of Alloying Elements on Steel."

This article and the next three articles will focus on the basic principles of heat treatment such as:

- The definitions of processes.

- Their meanings and selection.

- Quenching.

- Surface treatments, including nitriding up to thin-film depositions.

- Quality control.

- Troubleshooting.

What Is Heat Treatment as Applied to Steel?

Heat treatment - as applied to steel - can be defined as the application of heat to change a characteristic or condition of the steel. The amount of heat can be measured by the temperature of the steel being treated.

Temperature can be either cold or hot to the touch, therefore the process treatment temperatures can range from extremely cold to extremely hot. Or, in terms of temperature, the range can be from a cold negative temperature to a hot plus temperature.

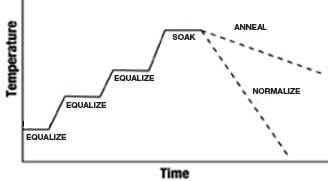

Heat treatment is the process of heating up to temperature, soaking at that temperature and then cooling down from the temperature.

Why Do We Heat Treat Steel?

Steel can be categorized in a variety of manners. The principle alloying element is carbon, which influences the steel's hardness and its mechanical properties.

It is necessary to apply heat to steel to enable its condition and mechanical properties to be changed to allow the steel to function either during manufacture or its operating life cycle.

Principles of Heat Treatment

If we consider the primary metal of steel, which is iron, there are a number of features that we can observe immediately about the metal:

- It is stable at room temperature.

- It is magnetic.

- It can have a shiny finish. In other words, it polishes to a bright shine.

- It has a high density (it is heavy).

- It is ductile (it can bend or be shaped easily).

Consider a straight vertical line as being an iron and temperature line combined. If we look at the line in the vertical configuration at room temperature, the iron is stable.

To understand what happens to iron when heat is applied, you must first know about ferrite, a condition in iron that has a number of inherent properties at room temperature such as a large grain size, a low hardness, good ductility and is easily machinable.

The ferrite condition exists in a particular crystal form and will exist at low temperatures. Iron is therefore made up of millions of tiny crystals much like sugar or salt. Those crystals are bound together in what is called a lattice structure.

The ferrite condition of iron can be compared to water, or H2O to be more precise. H2O exists in three forms: ice, liquid and vapor. Each of the three phases or conditions is still H2O, but they each exist in a different crystal form. Similarly, ferrite is one of the conditions of iron.

As heat is applied to iron, a number of things begin to happen to the shiny piece of steel that is being heated. The oxygen in the air will begin to react with the shiny surface of the iron to form Iron Oxide. As the temperature is increased, the reaction between the iron and oxygen becomes more aggressive, and a visible product begins to form on the surface of the iron, which is known as scale.

Once the steel reaches an approximate temperature of 1,350xF, a change in the structure takes place as well as the phase. The phase changes from ferrite to austenite. In addition to this, the crystal structure changes from body-centered cubic to face-centered cubic.

An indication of the change occurring is that the ion will lose its magnetic property, which can be seen by testing the surface of the steel with a magnet. Protect your hand and fingers when testing for the loss of magnetism from the hot steel.

What Does the Crystal Structure Look Like?

As the iron is heated up to above the lower transformation temperature of 1,350xF the crystal structure transforms to a face-centered cubic structure. Therefore, we can say that in order to make the phase of austenite, we need to apply sufficient heat to create the phase.

In addition to this, there is a growth that will occur due to the atomic structural change. Therefore, the size of the mold will change as it is heated. This is called growth and should not be confused with distortion.

So by definition, the lower transformation temperature (or the magnetic change line) is the temperature that the ferrite phase (a body-centered cubic structure) begins to change to austenite (a face-centered cubic structure).

What Then Happens to Steel?

Steel is simply an alloy of iron and carbon.

The line at 0.77 percent carbon is known as the eutectoid line. To the left of the line, the steels are known as hypo eutectoid steels (ferrite condition) and to the right of the line, the steels are known as hyper eutectoid steels (cementite condition). In order to establish what the upper change temperature would be to ensure a complete phase change form ferrite to austenite, one would need to know the carbon content of the steel. In other words, if we consider a steel at 0.40 percent carbon, we would look for a 0.40 percent on the horizontal carbon line and extend the line vertically. At the point where the line intersects the upper change line, the intersect point would extend a line horizontally to intersect the vertical temperature line. This would be the temperature where the ferrite has changed fully to austenite. Once the austenitizing temperature has been established, then approximately 50xF is added to that temperature to ensure that the steel is in the austenite region for full transformation. If the steel is left at a temperature that is in the transformation area of austenite + ferrite, then a mixed phase will exist and will not fully transform. Both phases have different volumes.

Once the steel is in the austenite region, it is necessary to cool it down to create the particular phase that is necessary for the steel to function, either for machining or for performance. The rate at which the steel is cooled will determine the phase or microstructure. The cool down can be slow or fast, depending on what is to be accomplished.

By controlling the soak temperature and the cool down rate of the steel, we can determine the process to be accomplished. Those processes include annealing, normalizing, stress relieving, hardening and tempering.

What Is Annealing?

Annealing is the process of heating the steel to a particular temperature in the austenite region and cooling down the steel very slowly. There are many derivatives of the annealing process, but generally the process is a slow cool process.

Another derivative of the annealing process is known as sub-critical anneal. This process involves soaking at a temperature below the lower transformation line, in the region of 1,200xF to 1,300xF, until the steel has equalized across its cross-section in temperature, followed by a slow cool. Slow cooling can mean a cooling rate between 5xF per hour up to 50xF per hour.

As can be imagined, the cooling period can be a considerable amount of time. It should be noted that the nickel alloyed steels and the A series tool steels should be cooled very slowly, as nickel will cause an air-hardening effect.

Other Types of Annealing:

- Bright Anneal. This method is a method of annealing which uses a protective atmosphere to prevent the steel surface from oxidation.

- Process Anneal. This procedure is done at a temperature close to the lower critical line on the iron carbon diagram. Sometimes confused with sub-critical annealing, it is used when considerable cold working is to follow.

- Recrystallization Anneal. Once again, this is a process often mistaken for subcritical annealing. It is used after cold working to produce a specific grain structure.

- Sub-Critical Anneal. This method is used on cold-worked steel and is carried out below the lower critical line on the iron carbon equilibrium diagram. It is sometimes applied to tool steels that have been over tempered and require annealing before hardening and tempering.

- Spheroidize Anneal. This process is a controlled heating and cooling procedure to produce spheroidal or globular cementite particles. It is usually applied on high carbon steels for good machining characteristics such as high alloy steels and tool steels.

- Isothermal Annealing. The process temperature of this procedure is determined by knowledge of the steel's carbon content. The steel is then taken to that temperature and cooled down to a holding temperature that allows the steel to transform isothermally.

- Full Anneal. This is a process that involves raising the steel's temperature up to the sustenite region followed by a slow cool.

What Is Normalizing?

Normalizing is a process that makes the grain size normal. This process is usually carried out after forging, extrusion, drawing or heavy bending operations.

When steel is heated to elevated temperatures to complete the above operations, the grain of the steel will grow. In other words, the steel experiences a phenomenon called "grain growth."

This leaves the steel with a very coarse and erratic grain structure. Furthermore, when the steel is mechanically deformed by the aforementioned operations, the grain becomes elongated.

There are mechanical property changes that take place as a result of normalizing - inasmuch as the normalized steel is soft, but not as soft as a fully annealed steel. Its grain structure is not as coarse as an annealed steel, simply because the cooling rate is faster than that of annealing. Usually the steel is cooled in still air and free from air drafts. The process temperature is virtually the same as for annealing, but the results are different due to the cooling rate.

The process is designed to:

- Give improved machining characteristics.

- Ensure a homogenous structure.

- Reduce residual stresses from rolling and forging.

- Reduce the risk of "banding."

- Help to give a more even response to the steel when hardening.

What Is Stress Relieving?

Stress relieving is an intermediate heat treatment procedure to reduce induced residual stresses as a result of machining, fabrication and welding. The application of heat to the steel during its machining or fabrication will assist in removing residual stresses that will, unless addressed during the manufacturing by stress relieving, manifest themselves at the final heat treatment procedure.

It is a relatively low temperature operation that is done in the ferrite region, which means that there is no phase change in the steel, only the reduction of residual stresses. The temperature region is usually between 800xF to 1,300xF. However, the higher that one goes in temperature, the greater the risk of surface oxidation there is. It is generally better to keep to the lower temperatures, particularly if the steel is a "pre-hard" steel. The hardness will be reduced if the stress relieve temperature exceeds the tempering temperature of the steel.

There is a general rule of thumb for time at temperature. It must be stated that the time is taken when the part is at temperature, not when the furnace is at temperature. The time at temperature for the processes of full anneal (not spheroidize anneal), normalize and stress relieve is 60 minutes at part temperature per one-inch of the maximum cross-sectional area.

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Tool Steel and Heat Treatment, Part 1

An introduction to heat treatment for the moldmaker.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)