Smart Machining

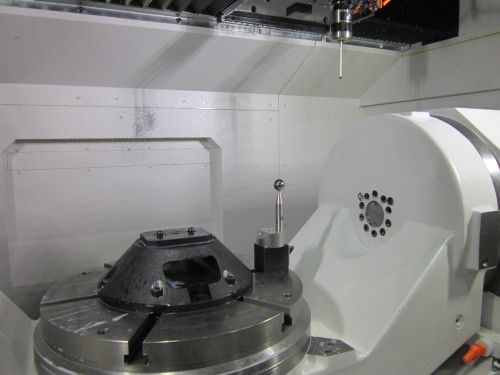

Among the highlights of Okuma’s recent Technology Showcase event were productivity-enhancing “apps” for the company’s open-architecture CNC; a tool monitoring and adaptive control system; and an auto-tuning system that eases error compensation on five-axis machine tools.

An system used to automatically measure and compensate for geometric error in five-axis machine tools was a big draw at the event. Click here for more information on this and other technology on display.

Manufacturing technology isn’t just getting faster and more efficient—it’s also getting smarter. That was a major takeaway from Okuma’s 2013 Technology Showcase at its Charlotte, North Carolina headquarters, where the company and members of its Partners in THINC collaboration network highlighted various systems that make machining easier and more efficient, perform tedious tasks automatically and behind the scenes, and customize how users interact with their equipment, among other advantages. Click here for a few examples of what I saw.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=300;quality=90)