SLIDESHOW: Technology Showcase, A to Z

From design to first shot, 2016 featured new and improved technology solutions for today's mold builders. Here is a quick look at some of the products and equipment from last month that you may have missed.

The past 12 months were not only spent battling ongoing moldmaking challenges, but also brought to light new moldmaking challenges, as well as new product and equipment enhancements to help face them head on.

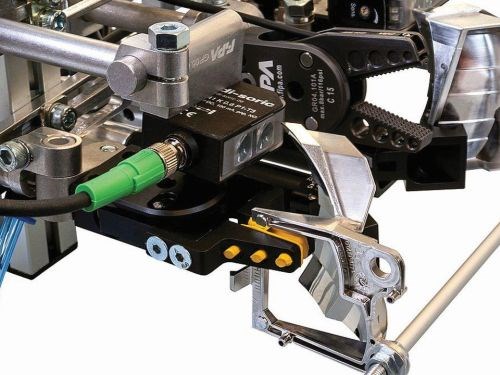

Automation. Smaller shops investing in automation while larger shops are evaluating six-axis robots versus traditional automated configurations to increase automation flexibility. Fully automated milling of hardened mold inserts is the next level of automation in moldmaking. A growing trend in machine-side systems robots for placing inserts in molds, labeling, part removal, etc. and collaborative robots that interact safely with humans.

Additive manufacturing. Increased interest and use of several additive technologies, such as laser cusing of steel, hybrid additive machines, 3-D printing of plastic parts and conformal cooling.

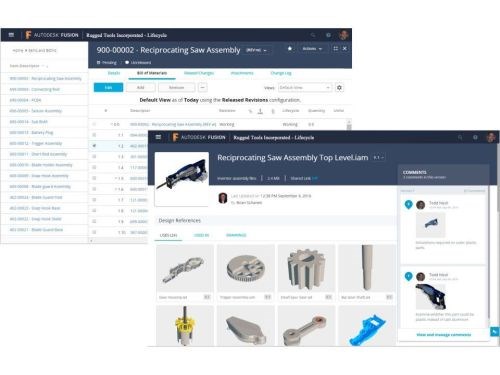

CAD/design. Design software that features 3-D simulation and analysis, or even virtual reality imaging, can help moldmakers fine-tune part and mold manufacturability before cutting steel. Model-based design and 3D CAD with embedded dimensional data, and CAD/CAM capable of preparing complex models with a system capable of importing data from many different sources.

CAM and programming. Because moldmaking is both design and machining, software that is proficient at both CAD and CAM is key, especially with large files. Feature recognition and speed are what moldmakers are looking for. Another big area of focus for CAM is finishing, and for moldmaking that is the largest part of the machining process.

Machining. Five-axis machining continue to be adapted at a higher level. Finding ways to productionize mold building through the use of multi-tasking machines or by using well-planned machining strategies like batching different jobs together for lights-out operations. Increased use of modular workholding systems in a shop’s small component area.

Cutting tools. Vending machines for cutting tools and other commodity items to ensure availability and accountability, more modular tooling and continued interest in hard cutting capabilities and cutters as well as high-feed milling cutters for difficult-to-machine materials. Finding the right cutting tool is still a challenge, moldmakers are seeking cutting tool manufacturers that enhance systems/software that provides tool recommendations specific to the machine and application.

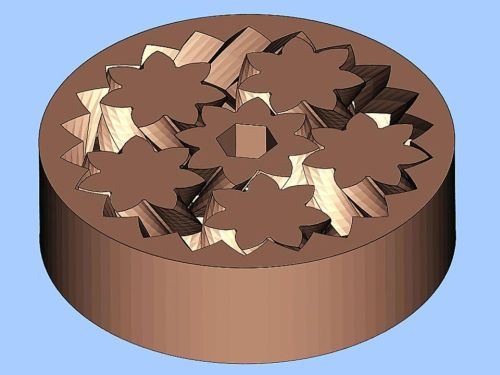

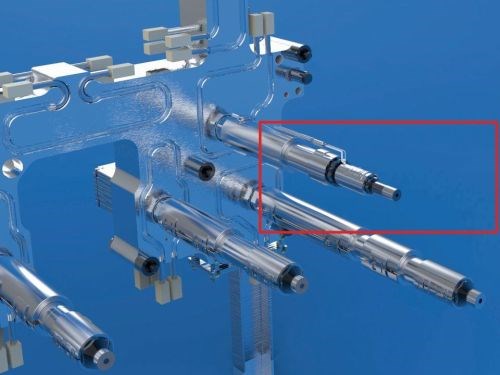

Components and mold material. The use of unconventional mold movements for part ejection, an increased use of standard mold components to control mold quality and speed build times, using localized fast heating during cycles to help with flow and cosmetics and aluminum tooling.

Quality, inspection and measurement. Increased use of machine tool touch probes, measurement data from on-machine inspection, in-process inspection using model-based definition and CT scanning of molded parts. Developments in quality data management software, measurement software, and enhancements of computer tomography and white light sensor technology.

Molding. Process validation using simulation to analyze the mold before steel is cut. This is also being incorporated with in-mold cavity pressure sensors to provide feedback from the floor.

Maintenance, repair and surface treatment. Increased use of laser welding, and using spotting presses for mold inspection and verification, in addition to mold maintenance and repair

This slideshow is a quick look back at some of the products and equipment that you may have missed.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More