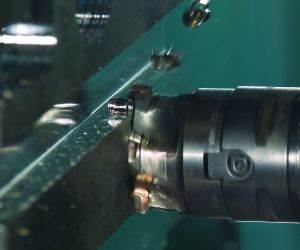

Everstampi sought a new micro-drilling solution to drill precise holes into difficult-to-machine mold steel. The micro drill shown here supports machining in all ISO materials and is available in a wide range of cutting tools and lengths. Photo Credit (including landscape image): Sandvik Coromant

The concept of “fail fast, fail often” has its critics and advocates. While failure can be a significant turning point in a product’s design, no manufacturer wants it to happen. So, when mold builder Everstampi was looking for a new micro drilling tool, it understood that failure was to be expected. However, to its surprise, solid round tool (SRT) micro drills from Sandvik Coromant failed neither fast nor often. Instead, the company has experienced just a single tool breakage.

Laying the Groundwork

Working in the plastics industry for more than 30 years, Everstampi designs, manufactures and tests molds for small- and medium-sized plastic details for various sectors. Supporting industries including cosmetics, food and beverage, household cleaning items and pharmaceuticals, Everstampi guides its customers through every step of the mold and die process — from the presentation of mathematical models, drawings and prototypes, through to mold design, manufacturing and commissioning.

Everstampi sees automation as the future for mold manufacturing and has recently made several technology investments. The company partners with leading CAD/CAM providers, such as Autodesk and TopSolid, and has made a significant investment in its machine technology, including four milling machines, four turning machines, four EDM machines and one drilling machine.

Everstampi is a leading manufacturer of high-volume injection molds with some of the shortest production cycles in the market. So, it chose to invest in tools from Sandvik Coromant for a micro-drilling solution. Photo Credit: Everstampi

Everstampi also invests heavily in cutting tools. Its workshop includes four milling machines, including a Mikron HPM 1350U machining center for producing molding blocks and four lathes and a Hardinge Quest series 8/51 super-precision turning center dedicated to turning hardened steel. These investments have paid off, as Everstampi now manufactures high-volume injection molds with very short lead times.

Drilling Down

Micro-drilling techniques produce components such as molds and mold components for medical devices and surgical tools, aerospace parts and consumer electronics. However, it’s not just the micro size that presents a machining challenge. Mold builders are also required to machine increasingly smaller parts from notoriously difficult-to-machine materials, like stainless steel, ceramics and titanium. In addition, delivering high surface quality while maintaining cutting tool life is no easy feat — many expect to fail often.

The company sought a new micro-drilling solution for one project to drill precise holes into difficult-to-machine mold steel. Everstampi had to drill holes in mold components made from ISO H steel with a hardness of 53-54 Rc, which generates heat during cutting and is very abrasive to the cutting edge. It’s not uncommon for micro drills to exhibit short cutting tool life, especially when machining tough workpieces.

“Honestly, our objective was to get the job done while breaking as few tools as possible,” Colombo Edoardo, production manager at Everstampi, says. “We were aware of the complexity of drilling many tiny holes into such a hard material, so we would have been satisfied if we only broke several tool bits.”

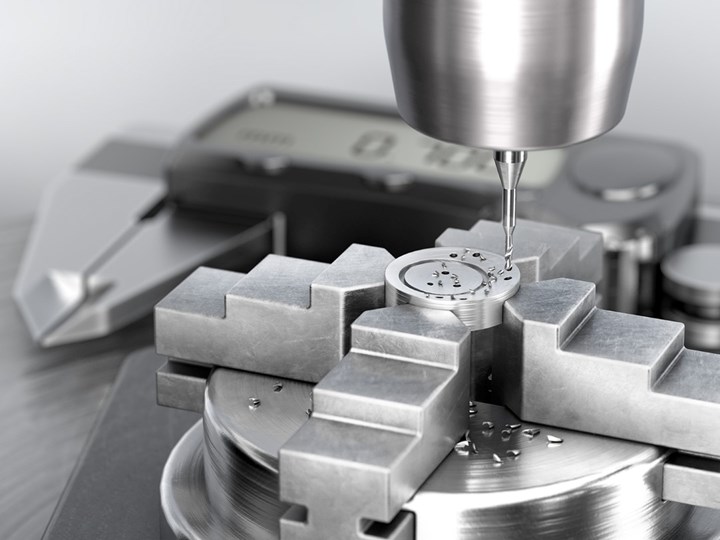

All of this makes the design, quality and type of coating for the drill critical considerations if the cutting tool is to live up to expectations. Needing a resilient, reliable solution for this drilling dilemma, Everstampi invested in Sandvik Coromant’s CoroDrill 862 with GM geometry cutting tool, a solid carbide and polycrystalline diamond (PCD) micro drill ideal for precision drilling and making holes from 0.30 millimeter to 3 millimeters in diameter.

CoroDrill 860 with GM geometry features a new grade, innovative flute design with a multilayer physical vapor deposition (PVD) coating on the drill tip. According to Edoardo, the results are improved drilling capabilities across various materials and applications. In addition, the cutting tool is designed for applications where hole quality is critical, making it an ideal choice for Everstampi’s general engineering requirements.

“To have just one tool break during such intensive drilling isn’t only brilliant, it’s near impossible.”

“One of the most innovative qualities of the drill is its advanced geometry, with the double margin adding stability, increased core strength and reinforced corners, all of which contribute to process security and finished hole quality. In addition, the flute is highly polished, which helps improve chip evacuation and reduces heat buildup during the drilling process,” Edoardo continues.

CoroDrill 862 supports machining in all ISO materials and is available in various cutting tools and lengths. Put simply, this drill can make a real difference to the quality of the finished product. But will the cutting tool last? The main factors to consider to answer that question are the workpiece’s cutting speed and material hardness.

Everstampi invested in a solid carbide and polycrystalline (PCD) micro drill ideal for precision drilling and making holes from 0.30 millimeter to 3 millimeters in diameter. Photo Credit: Sandvik Coromant

Selecting the Tool

When choosing a cutting tool, Sandvik Coromant recommends first assessing the hole type and required precision, as each of these factors influences cutting tool choice. Then, when the hole is analyzed, consider the workpiece material, component shape and quantity. The company recommends asking these three questions:

- Does the material have good chip-breaking qualities?

- What are the machinability and material hardness properties of the workpiece?

- Does it contain alloy elements?

Next, consider the machine itself, including its stability and the type of operation. Finally, shops should ask which type of toolholders are being used, as the ability to clamp the tool securely and precisely influences productivity just as much as grade and geometry.

“Based on similar criteria, Everstampi selected the CoroDrill 862 cutting tool in five different diameters (between 0.5 millimeter and 0.9 millimeter) because each comes with an increase of radial depth of cut, which means deeper slots can be cut into the workpiece. In this case, each of the five selections can drill hole depths of up to nine times diameter (xD),” Edoardo says.

Everstampi selected its tools without coolant supply, which would ordinarily aid chip removal. However, it felt this was unnecessary as the micro drills had the correct diameters and depth to perform the application well. Following this request, Sandvik Coromant suggested the shop favor peck drilling for more effective machining.

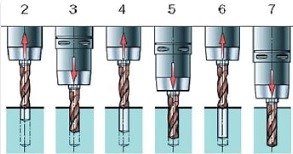

The peck drilling process in action to help with chip evacuation and to support cutting tool accuracy. Photo Credit: Sandvik Coromant

“Peck drilling involves plunging the drill partway through the workpiece,” Fabio Capone, solid round tools specialist at Sandvik Coromant, explains. “Ideally, you need to drill down no more than once or twice the diameter of the drill, then retract it to the surface. This action is repeated until the hole is finished. When there’s no use of internal coolant, like in Everstampi’s case, we advise this drilling method, as it aids the chip evacuation process, supports cutting tool accuracy and prevents chip breakage.”

Small Project Yields Big Success

To Everstampi’s surprise, tool breakage was not an issue. Instead, it experienced just one broken drill after machining approximately 1.5 meters of a hole per drill. “It’s not that we did not trust the product. But, in reality, it’s pretty unfeasible for micro drill machining such a hard material to do so successfully and without significant breakage,” Edoardo says. “To have just one tool break during such intensive drilling isn’t only brilliant, it’s near impossible.”

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Release the Entire Potential of Your Machine Tool Investment

Making tooling a part of your machine tool purchase via a tooling certificate can save you time and money.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Optimize Moldmaking Milling Operations

The lead angle of your cutter has a dramatic effect on not only the chip that you generate, but also the cutting forces in both the axial and the radial directions.

Read More

.png;maxWidth=300;quality=90)