Rapid Prototyping and Tooling - State of the Industry 1999: Executive Summary

Rapid prototyping (RP) refers to the physical modeling of a design using a special class of machine technology.

Rapid prototyping (RP) refers to the physical modeling of a design using a special class of machine technology. RP systems quickly produce models and prototype parts from 3D computer-aided design (CAD) model data, CT and MRI scan data, and data created from 3D object digitizing systems. Using an additive approach to building shapes, RP systems join liquid, powder and sheet materials to form physical objects. Layer by layer, RP machines fabricate plastic, wood, ceramic and metal parts using thin, horizontal cross-sections from the computer model. Some argue that free-form fabrication (FFF) more accurately describes this class of technology, particularly as its applications expand beyond fast prototyping.

Manufacturing organizations use RP to produce models and prototypes of injection-molded parts and metal castings that go into everything from copy machines, computers and cellular phones to automobile instrument panels, airplane subassemblies and medical diagnostic equipment. RP acts like a lubricant that helps smooth and streamline the product development process. Most companies use it to help improve time to market. As a visualization tool, RP helps companies reduce the likelihood of delivering the wrong product, or a poor quality product, to the marketplace. For some, it may be helpful to view rapid prototyping as a journey, not a destination - a strategy, not a technology.

Methods, processes and systems for rapid tooling (RT) also are developing, many of which are new and not well understood. As an emerging technology, the definition of RT is often debated and not clearly defined. Most would agree, however, that RT is driven from an RP process - the key to making it rapid. The digital data from a CAD solid model and RP processes are important elements of rapid tooling. An indirect approach to RT accelerates the tooling process using RP patterns that are, in turn, used to produce molds. Another approach to RT is to produce core and cavity mold inserts directly from an RP process such as selective laser sintering.

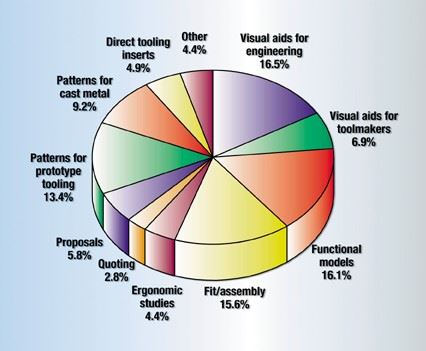

How RP Models Are Being Used

Chart I shows how companies are using RP models. Almost one-third of all RP models are being used for fit and function applications, an estimate derived by adding together the "Fit/assembly" and "Func-tional models" segments in the chart. Nearly another one-third serve as visual aids for engineering, toolmakers, requesting quotes and presenting proposals, an estimate also derived from adding together the segments. About 28 percent of RP models are being used as patterns for prototype tooling and metal casting, as well as for tooling inserts.

A Challenging Time

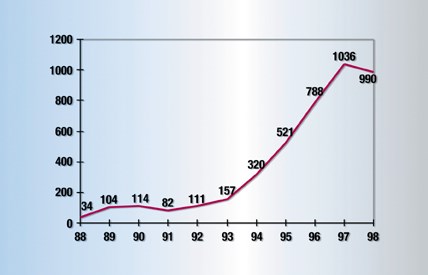

On the heels of a weak 1997, revenues from RP sales and services fell more sharply than in any previous year. This downturn follows years of impressive growth for most of the 1990s, when annual growth of 35 to 50 percent was common. The slump in the industry that began in early 1997 has continued through 1998 and is expected to persist in the future.

Without further consideration, the 1998 performance could be taken as an indicator of the future demise of the RP industry. Yet, there are many factors that have coalesced to produce a weakening of the RP industry. Most notably, and perhaps most ignored, is that new technology follows a somewhat predictable growth curve as the concepts and practices are adopted. It is not unusual for a technology to experience rapid growth from purchases by the early adopters, only to be followed by a decline. RP has reached this period of slowed growth.

RP's growth and success are also affected by the state of the CAD industry. CAD solid modeling, the fuel that stimulates RP sales, has begun its dramatic growth phase. Experts predict more than 100 percent growth in solid modeling for the next couple of years. With this growth, RP will have many new opportunities for sales of systems and services. No matter what you read or hear, do not underestimate the role of solid modeling in the development of markets for rapid prototyping and 3D printing.

Companies are demanding technology that is more mature than RP can currently deliver. Many people in the industry are asking for machine technology that is less expensive to buy and maintain and easier to use. Indeed, RP system prices and the overall cost of ownership must drop further. Expect the price of both systems and services to decline further in 1999 and into 2000.

Graph 1 shows the growth trend of RP unit sales worldwide. Graph 1 reflects the dramatic downturn in last year's sales.

Service Bureau Market Saturation

The early success of the service bureaus (SBs) has negatively impacted the RP market. Having reached a temporary level of saturation, the SB market has become highly competitive. This has led to the demise of some SBs, which has made many used RP systems available for purchase. With the availability of used equipment, the demand for new machines has declined. This is especially true for SBs that are seeking to minimize overhead expense in light of dramatically reduced pricing and falling profit margins. Competition also has led to a sharp reduction in model prices at SBs. This has affected system purchases by end-user companies, since many choose to buy low-priced parts from SBs rather than investing in new RP equipment.

Good relationships with customers are important. Still, even with strong relationships, the most loyal customers are not nearly as loyal as they once were. With three or four "hungry" SBs at your back door, there is good reason to get quotes from each of them. With so many competitors offering models of acceptable quality, a SB must sell the customer with almost every job. This makes it hard for SBs to predict revenues from year to year, and even from month to month.

Given the current market conditions, don't expect many new startup companies to appear in the near future. Also, it's a pretty safe bet that SBs will not be buying equipment like they did in most of the 1990s. It's unclear whether SBs will consolidate, given the poor results by those who have attempted this in the past. Consolidation, mergers and acquisitions appear to have advantages in the economies of scale that come with the sharing of people, machines and marketing dollars. However, there are risks and obstacles in this course of action that can easily overshadow any benefits. Also, in the service business, customers may prefer to work with smaller, personalized companies. SBs that employ fewer than 20 people make it easier for customers to get to know and interact regularly with company owners and top management.

Advances in Rapid Tooling

Two broad categories of rapid tooling exist. One category involves indirect approaches that use RP master patterns to produce a mold. Examples of indirect methods include silicone rubber tooling and 3D Keltool from 3D Systems. The second category is a direct approach, meaning that an RP machine builds the actual core and cavity mold inserts. RapidTool from DTM, direct metal laser sintering from EOS, and Direct AIM from 3D Systems are examples of direct methods.

Many companies are pursuing the development and commercialization of RT because of its market potential. In 1998, the secondary RP market segment, which includes RP-driven tooling and core and cavity inserts created directly from RP processes, grew 17.5 percent to an estimated $376.7 million. No one knows for sure how big this market segment will become, although it's safe to assume that someday it will become large.

The interest in RT is fostered by the potential to slash both cost and time in the development of tooling and the production of parts. Companies recognize opportunities to apply methods of RT to prototype, bridge, short-run and production tooling. RT also offers a potential benefit that one cannot realize with conventional machined tools. With RT, you can optionally embed conformal cooling lines in the mold. Conformal cooling lines are copper lines or channels fabricated directly into the mold. These channels conform to the geometry of the mold cavity, thus removing hot spots in the mold and reducing injection molding cycle times. Research indicates that cycle time reduction using conformal cooling has a significant impact on part cost and production rates.

Developments and Trends Worldwide

As many as 22 companies worldwide now manufacture and sell RP systems. Nine are from the U.S., eight are from Japan, two are from Germany, and one each from Israel, China and Singapore.

No RP system manufacturers were forced to sell out or shut down last year, although a couple of them were on the edge. This has not been the case in past years. For example, BPM pulled the plug and closed its doors in October 1997.

The RP system manufacturers in Japan seem content with their low number of unit sales. In the past four years, the most successful companies have sold no more than 25 units in a single year. In most years, sales from these companies have been in the 14 to 20 unit range. The most successful U.S. companies have been selling 100 to 275 units during this same period.

Europe's development of RP systems has been limited, yet one should not underestimate its role in the industry. Important partnerships have developed, leading to new ideas, system refinements and important applications research, particularly in secondary processes such as metal casting.

A staggering number of new RP developments are underway at universities, corporations and government labs around the world. The increase in the number of RP-related patents that have been issued in the U.S. alone is impressive. The future challenge will be to package these technologies into commercially viable products.

Summary

The rapid prototyping industry is questioning the future of its technology. Many are evaluating where the industry is and how it got there. To some, this once sparkling technology now has a tarnished appearance and an uncertain future.

In 1998 the industry was stagnant. This was a year where equipment manufacturers' stocks remained low; where service bureaus, both large and small, failed; and where innovation and new developments came at a slower than desired pace.

Countless benefits of RP abound, with RP users reporting almost unbelievable time and cost savings from applying this remarkable technology. This is at odds with the stalled growth in the marketplace, and it is causing vast confusion among vendors, customers, service providers and investors. Some believe the technology may fade over time while many others dismiss the idea. Companies about to make strategic decisions related to rapid prototyping are especially concerned that they might make the wrong decision. Why has the RP market weakened, will it recover, and what should a company do in the meantime? The full report answers these puzzling questions.

This document provides a sampling of the information published in Rapid Prototyping & Tooling State of the Industry: 1999 Worldwide Progress Report. The full report focuses on many important facets of rapid prototyping and tooling, including the industries being served, applications, revenues and unit sales, and forecasts. For more information contact Terry Wohlers, president of Wohlers Associates, Inc. (Fort Collins, CO) at (970) 225-0086.

Related Content

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreRead Next

3D Printers Lead Growth of Rapid Prototyping

Bringing rapid prototyping capabilities in-house is becoming a reality for many plastics manufacturers, thanks to more affordable, faster, and easy-to-use 3D printers.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More