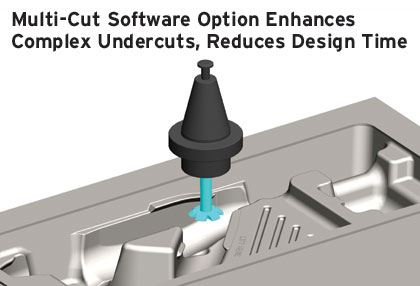

Multi-Cut Software Option Enhances Complex Undercuts, Reduces Design Time

Case Study/Software, Electronics

Flexpak Corp. (Phoenix, AZ)—an ISO 9001:2008 certified custom thermoformer for the medical, food, electronics and retail industries—also has an internal mold shop that manufactures custom thermoform molds made from certified high-grade aluminum, using Surfware’s (Camarillo, CA) SURFCAM CAD/CAM software with the new “3-Axis Multi-Cut” option to dramatically enhance undercut machining.

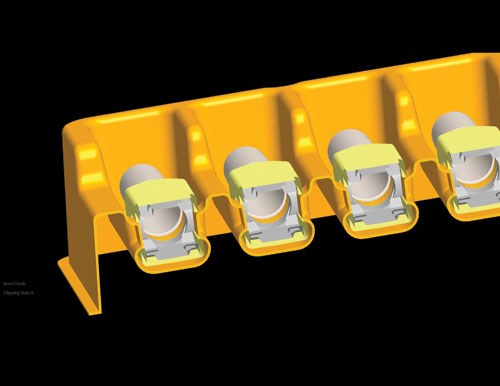

According to Thomas Sipek, Flexpak’s Director of Tooling, when producing thermoform molds, complex assists are made to help push the product close to the mold before forming, using a low heat transfer material. Then, after the parts are molded, the parts are trimmed from a variety of dies that consist of match metal, forged or steel rule.

“Some of the challenges we incur during manufacturing thermoformed tooling is repeatability,” Sipek explains. “We provide prototypes molds that produce production quality parts. Our customers approve the prototypes for form, fit and function. Then we have to reproduce the precise prototype mold geometry in the production multi-cavity molds. The product fit can consist of a snap fit to hold the product in for a six-foot drop test without damage, to having a surgeon remove a product with one hand in an operating room.

“Thermoforming molds may not seem as complex as injection molds, but the same theory exists—move and form plastic to precise details,” Sipek continues. “Injection molds have shutoffs and parting lines that cause flashing and require greater tolerances in the tenths of a thousandth of an inch. In thermoforming, the sheet material is heated and shaped over the mold. The major issue is thinning of the sheet in critical areas. The tolerances on the molds are usually in thousandths of an inch.”

The mold finishes can range from a bead-blast textured finish to a highly smooth, chromed-look finish. “Mold finishes can result in reduced glare on the finished product to help a customer see through the package,” Sipek says. “A highly polished finish can help mold release when undercuts are manufactured in the mold. Some requirements even consist of Teflon coating the molds for product release.”

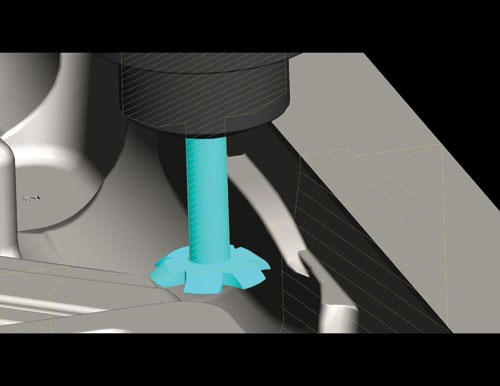

Improving the Undercut

According to Sipek, it was challenging for Flexpak to reproduce the precise prototype mold geometry of undercuts to the multi-cavity molds. “Undercut details are what holds the product in the package,” he elaborates. “Before using the new ‘3-Axis Multi-Cut’ functionality, we had to depend on manual mills or hand work to finish the undercut areas. This left us with too great of a variable of a critical area of the mold cavities. The requirement to machine undercuts with great accuracy in a Z plane surface in a 3-D model has always been a challenge prior to Surfware’s new ‘3-Axis Multi-Cut’ functionality. However, now SURFCAM’s ‘3-Axis Multi-Cut’ allows us to program and cut surfaces that only 4- and 5-axis machines and toolpaths can accomplish. Our critical medical projects require complex, three-dimensional undercuts. Using ‘3-Axis Multi-Cut’ allows us to complete that with stringent details.”

Using “3-Axis Multi-Cut” also has improved Flexpak’s moldmaking process with repeatable results. “When undercuts are involved in holding a product they may be subjected to a pull test,” Sipek explains. “The pull test will determine what is too high or too loose of a fit. With the ability to produce undercuts exactly as designed in the prototype, we save time and it’s more accurate. This also prevents downtime in the thermoformed press during first article approval and that makes us more efficient. Some savings have been recorded as much as 40 to 50 hours per mold.”

Flexpak is extremely satisfied with SURFCAM’s new “3-Axis Multi-Cut” functionality. “We now can provide our customers with the production products that match the prototype samples they approved,” he concludes. “A faster approval means a reduction in time to market—which also has improved our overall sales.”

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreRead Next

High-Performance Milling with a Tool Engagement Controlled CAM System

It is now possible to increase productivity without increasing cost by using a new milling technique—tool engagement milling.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)