Diamond Tool & Engineering is a 33-year-old full-service precision moldmaker employing 30 team members, and producing over 100 small-to-medium-size molds ranging from 8 x 8 to 30 x 44 inches/20 x 20 to 76 x 112 centimeters) and repairing/rebuilding 50 additional molds in a normal year. This work is done from two facilities totaling 17,050 square-feet/1,584 square meters in Bertha, Minnesota. Diamond runs two shifts/day, plus operates three highly automated robotic cells that run nights and weekends. Shown above are Diamond team members Zachery Johnson, designer (top left/hands only), Jeff Schwartz, toolmaker (bottom left), Russel VandenHuevel, quality manager (upper right), Jamie Banister, CAM programmer (middle right) and Luke Miner, production manager (bottom right). Photo Credit: Diamond Tool & Engineering/Creative Technology Corp.

Diamond Tool & Engineering of Bertha, Minnesota, is a full-service mold builder specializing in very detailed, high-precision (±0.0001 inch/0.0025 millimeter) injection molds designed for very high-volume production (1 million+ shots) and used in the medical device, consumer products and electronic closures markets. However, the company also has made many precision molds for the automotive industry, including headlamp lenses, over the years. Diamond’s tools are typically used to injection mold high-temperature engineering thermoplastics like polyetheretherketone (PEEK). While straight injection represents the majority of its tooling, the company occasionally produces tools for injection specialties like gas-assist, microcellular foaming and micro molding, as well as for liquid silicone rubber (LSR), heat-cured rubber (HCR) and metal injection molding (MIM). Given its expertise, it’s no surprise that nearly all Diamond molds are produced in steel, much of it hard steels, with inserts, and with one to 32 cavities.

In addition to a collection of high-end CNC, plus sinker and wire EDM machines to support its high-precision work, the 33-year-old company also maintains a 140-ton electric press that can sample 95% of the tools it builds. Diamond claims that 98% of its molds are ready for production after initial sampling. While it doesn’t own a 3D printer, the company has produced molds using conformal cooling inserts, although Kent Smith, Diamond founder and president, acknowledges that his customer base has been slow to embrace the benefits of metal additive manufacturing (AM). Diamond also uses a lot of copper-beryllium for its inserts.

Seeking Greater Productivity

Diamond is known for producing very detailed, high-precision (±0.0001 inch/0.0025 millimeter) injection molds designed for very high-volume production (1 million+ shots) and used in the medical device, consumer products, and electronic closures markets. Maintaining tight geometric tolerancing is critical for its customers, hence the company frequently upgrades equipment and uses this Zeiss CMM to verify molds are machined to design specifications. Above, Samantha Wojtowicz, Diamond precision polisher works under a microscope to see fine details. Photo Credit: Diamond Tool & Engineering/Creative Technology Corp.

To ensure his shop stays competitive and his equipment maintains very tight tolerances daily, Smith continually invests in the company and exchanges equipment several times per year, explains Andy Walser, machine tool sales engineer at Minnesota-based distributor Productivity Inc. He adds that Smith has purchased several machines from Productivity since 2013 and is constantly seeking ways to increase efficiency and accuracy — from advanced EDM and CNC machines, to automated handling and palletization systems.

“Kent’s shop in Bertha typically handles the hard stuff that most other shops don’t want or can’t do, like very high-tolerance LSR molds where you have to flash in 0.0001 inch,” explains Walser. “He’s got a team of very skilled moldmakers and machinists and invests in high-end machines that can hold those tight tolerances. Not only is Kent willing to try something new, but he also lets his guys get involved in new machine purchases. He’s willing to let them spend time looking at machines in different places and then make test cuts. That gives his team confidence that what’s being purchased will fit their needs.”

When Smith and his team started shopping for their next machine tool purchase last summer, he says he didn’t have a particular machinery OEM in mind, although, ironically, he started out looking for a lathe, not a milling machine. What he did have was a good relationship with the team at Productivity. “I have a good amount of trust in their judgment and I really like Andy, who is very professional and does a really good job of presenting things,” says Smith. “When Andy told me they had an option that they feel offers a lot of value from Hwacheon, a Korean company known for its very high-end machines for moldmakers, I listened. Then, as we learned what these machines were capable of and started seeing test cuts from them compared to cuts from other high-end machines, I got a really good feeling about it.”

“By design and structure, Hwacheon machines are extremely stiff and stable and therefore capable of high-precision geometrical tolerancing.”

Hwacheon Machine Tool Co. Ltd. is a 77-year-old machinery OEM whose parent organization is integrated all the way back to the foundry and all the way forward to producing precision metal components for automotive powertrains systems. After seeing a Hwacheon lathe operating at Productivity’s facility, a small team from Diamond traveled to another moldmaker’s facility in St. Cloud, Minnesota, to observe a Hwacheon Sirius UM+ three-axis milling machine operating in real-world conditions.

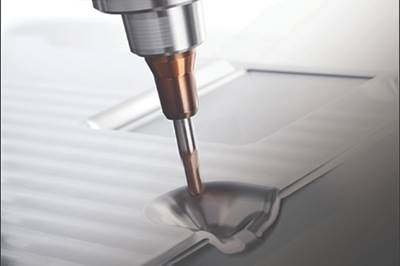

Hwacheon milling centers are known for their highly stable construction, thermal and vibration control, patented spindle technology and unique software that controls for constant loads on the spindle rather than constant feed rates. The latter enables moldmakers to achieve better surface quality, longer tool life with lower replacement costs, much less end mill chatter, and spindle and axle bearings that last longer while reducing cycle time by 20-30%. Photo Credit: Hwacheon Machine Tool Co. Ltd.

“Once we felt comfortable with the capabilities, tolerances, rigidity and thermal stability of this machine, we ordered a Sirius UM+ of our own. Plus, we found that we could order it with a 60-position tool changer, which was a big selling point so we could run unattended much of the time,” adds Smith. “Another selling point was learning how low the total cost of ownership was, even on a five-year-old machine. Then, of course, there was also ongoing support from Productivity, which always brings real value.”

Heart of the Machine

A great example of the capabilities of the Hwacheon Sirius UM+ is a mold that Diamond recently finished on the milling center. The four-cavity tool was designed to gas-assist injection mold highly contoured kayak paddle blades. After CMMing the cores and cavities, Diamond found they were repeatable to 0.0002 inch/0.0051 millimeter. Photo Credit: Productivity Inc.

Hwacheon has sold machining centers in North America since the early 1990s. In 2014, regional headquarters was moved from Vernon Hills, Illinois, to Lincolnshire, Illinois, in the Chicago suburbs. Robert Nedler, Hwacheon managing director/VP of sales and marketing North & South America, explains that the company was the first machine tool company in Korea when it was founded in 1945 and Hwacheon is still family owned and operated. The fact that the parent company operates a foundry gives Hwacheon Machine Tool the ability to make its frames and to use special processes and alloys for its castings. That capability has proven especially helpful in developing the second-generation Sirius UM+, which debuted in 2020 and is based on the Sirius UM model first introduced in 2012. One of the unique aspects of the UM+ model versus its predecessor is its thermal management and vibrational damping control, which helps make what was already a very stiff and stable machine all the more so. Many essential features are said to differentiate Hwacheon machines from those of competitors.

“First, by design and structure, Hwacheon machines are extremely stiff and stable and therefore capable of high-precision geometrical tolerancing,” explains Nedler. “If you look at a machine’s frame structure, it’s the heart of the machine. If it’s weak or lacks stability, it will fail or you will have a miserable time chasing tolerances or surface quality. We take extra time to make our machine structures as perfect as possible, including avoiding too many contact points and hand scraping in tolerances. We don’t use shims, which are just band-aids to bring things back into alignment. That gives us a foundation with a super tight geometry. Also, all of our machines use what we call an overhead gantry wall design, which has proven to provide the highest accuracy for high-end mold production. Second, to control for displacement due to vibration and heat buildup, we use special damping materials placed at critical locations, combined with other design features that greatly reduce impact on the frame and, hence, on the machine’s stability. Third, our patented high-performance oil-jet spindle design doesn’t just put a cooling jacket around the spindle or motor. Rather it injects chilled coolant directly onto the hand-matched spindle bearings, permitting temperature control of ±0.10°C [0.06°F]. That enables better control of spindle growth, which is within 4 microns, meaning super tight tolerances.”

The Diamond team was impressed with the capabilities, tolerances, rigidity and thermal stability of Hwacheon milling centers. And once they learned it could be purchased with a 60-position tool changer, which

facilitates running unattended much of the time, they ordered their own Sirius UM+ model, which was installed at the very end of 2021. Above, Paul Enberg, Diamond steel finishing technician, works at the Hwacheon machine. Photo Credit: Diamond Tool & Engineering

Nedler notes that a lot of technology has gone into controlling the thermal stability of the headstock, which, in turn, enables Hwacheon to offer spindles capable of running at up to 45,000 rpm without losing accuracy. “Additionally, we use high-performance Fanuc controllers combined with our software, including real-time thermal displacement control, tool-load detection system and cutting-feed optimization system.” He adds that this allows moldmakers to fine-tune machine settings for individual application needs, including setting speed and acceleration/deceleration for faster roughing, better finishing or greater accuracy. “The software provides smoothing factors in the machine as well — nine for speed, nine for precision or smoothing, so 81 combinations in total versus perhaps four to six combinations offered by our competitors. Additionally, our Optima feature uses tool-load detection to provide feed rate control. It’s essentially sensing the loads on the spindle and adjusting speeds up or down to make standard machining 20-30% faster.”

Conventional machines control for a constant feed rate and accept variable loads on the spindle, Nedler explains. However, when machining deep cavities and corner pockets, the spindle can experience tremendous loads and use larger cutting surfaces on end mills. “By controlling for constant load on the spindle rather than constant feed rate, you achieve better surface quality, longer tool life and lower replacement costs, you greatly reduce end mill chatter, and the spindle and axle bearings last longer, yet you still achieve shorter cycle times — a true win/win situation,” he adds. “While other machinery OEMs are starting to offer this feature, we’ve had it on our machines for at least a decade.” He notes that the high quality of Hwacheon machines translates to a very low cost of ownership. “People are very focused on the price they’re paying at the moment, and they forget to ask what that machine will cost them in terms of downtime, repair and replacement over the long run.”

“We’re very pleased with our Sirius UM+, and it’s more than met our expectations,” Smith adds. “We’ve been astounded by the repeatability of this machine.”

Paddling Along

Diamond ordered a Sirius UM+ with a 20- x 30-inch/49- x 74-centimeter table, 60 tool changer, a 20,000 rpm spindle, 1,000 psi/6.9 megapascals coolant chip blaster and the highest end probing system/tool touch-off that was available. The machine was delivered on December 31, 2021, and has been in use since early this year. The team primarily uses the machine for semi-finish and finish milling. However, with 50 horsepower and 165 foot-pounds/221 newton-meters of torque, the spindle has plenty of power to rough cut if necessary.

“We’re very pleased with our Sirius UM+, and it’s more than met our expectations,” Smith adds. “We’ve been astounded by the repeatability of this machine.”

Shown from left to right are Andy Walser, machine tool sales engineer at Productivity Inc., as well as Paul Enberg, machinist/toolmaker, Kory Stave, machinist/toolmaker and Kent Smith, founder/president of Diamond Tool & Engineering, standing in front of Diamond’s Sirius UM+ milling center from Hwacheon Machine Tool Co. Ltd. Photo Credit: Productivity Inc.

He recalls that the team recently used it to cut four large (8- x 20-inch/203- x 508-millimeter) cavity and core blocks for a mold that would produce gas-assist injection molded kayak paddle blades. “These blocks featured complex 3D surface contours without a flat spot on them, and we ended up using a lot of different cutters — from half-inch [12-millimeter] end mills to 0.03-inch [0.74-millimeter] mills for semi-finishing and finishing,” continues Smith. “We loaded up the Hwacheon and ran it continuously for 48 hours, then pulled those blocks out and repeated the process. We have a Zeiss CMM for inspection and when measuring those blocks we found they were repeatable to 0.0002 inch [0.0051 millimeter], which is unbelievable accuracy. We are very, very pleased with the results we are getting and we’d definitely buy another Hwacheon machine.”

Related Content

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;width=70;height=70;mode=crop)