MMT Chats: Liberty Molds Talks Respirators, Reshoring and Recommendations

MoldMaking Technology's Christina Fuges chats with some of the Liberty Molds team about a Ford Motor Company respirator project in the fight against COVID-19, the Hurco machine delivery that was key, and their take on the virus' impact and reshoring.

MMT Chats: Liberty Molds Talks Respirators, Reshoring and Recommendations

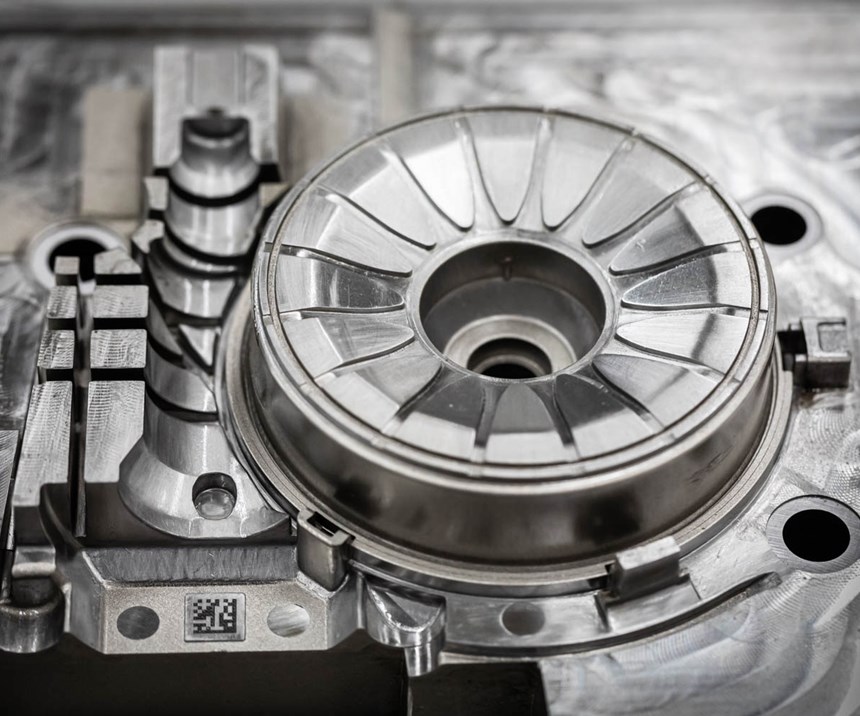

making respirator molds to fight covid-19 with hurco’s help

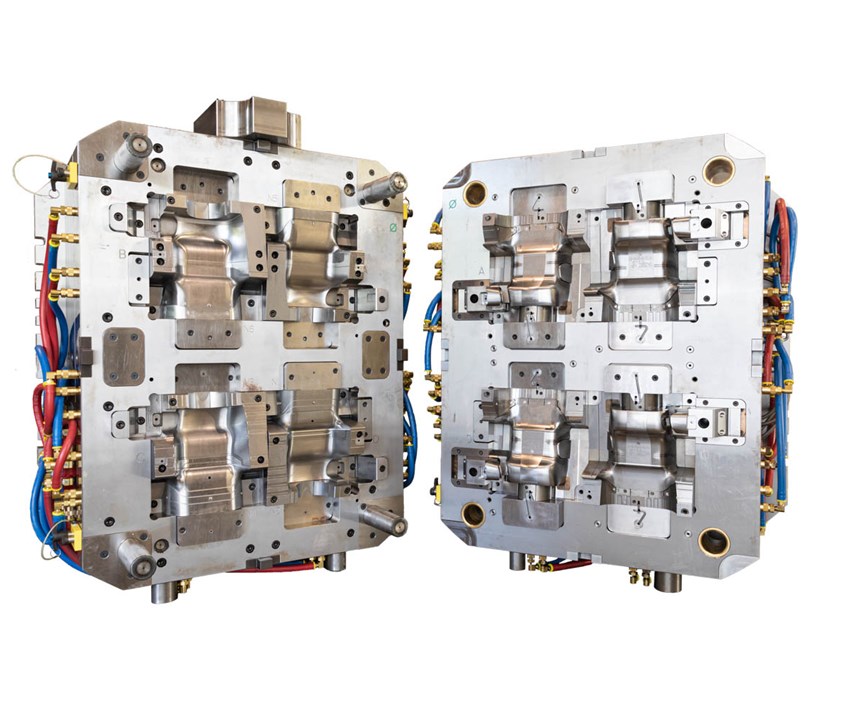

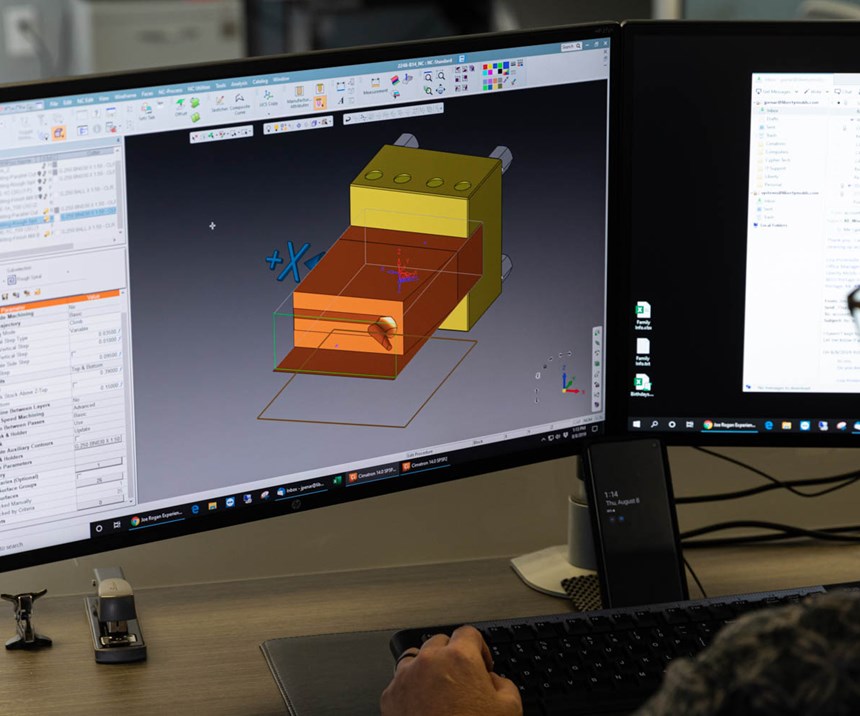

I sat down for a quick chat with Liberty Mold’s President Brian Scott and International Tooling Coordinator Mark Israels to get the scoop on the personal respirator system molds they took on and the earlier-than-expected purchase of two more Hurco machines to get the job done quickly. [Hurco delivered the machine tools within 72 hours!]

This “family” of 34—who primarily build automotive tooling—came together within 24 hours of a phone call to Scott about the need for respiration tooling. The team built 12 molds with a total of 10 different components.

Click here for the full 20-minute chat.

Related Content

-

Pennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

-

Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

-

International Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

.jpg;maxWidth=300;quality=90)