mHUB Lets Makers Collaborate and Create

Members of the American Mold Builders Association Chicago Chapter Education Committee explored a new resource for budding entrepreneurs and seasoned manufacturing professionals to learn, collaborate and create.

Share

Read Next

Members of the American Mold Builders Association (AMBA) Chicago Chapter Education Committee explored a new resource for budding entrepreneurs and seasoned manufacturing professionals to learn, collaborate and create. MMT invited Chicago Chapter Coordinator Karen Norville to share the experience.

On Tuesday, December 5, Chuck Klingler, Chicago AMBA president and vice president at Janler Corp, Francine Petrucci, president of B A Die Mold, Inc., Greg Osborn of Synventive Molding Solutions and I visited and toured a new, innovative manufacturing community in Chicago. mHUB opened in early 2017 to promote growth in manufacturing through physical product innovation and commercialization. Located at 965 W. Chicago Avenue (conveniently close to the Blue Line, one of Chicago’s commuter “L” lines), mHUB brings together engineers, designers, developers, manufacturers and entrepreneurs to collaborate on physical and digital projects.

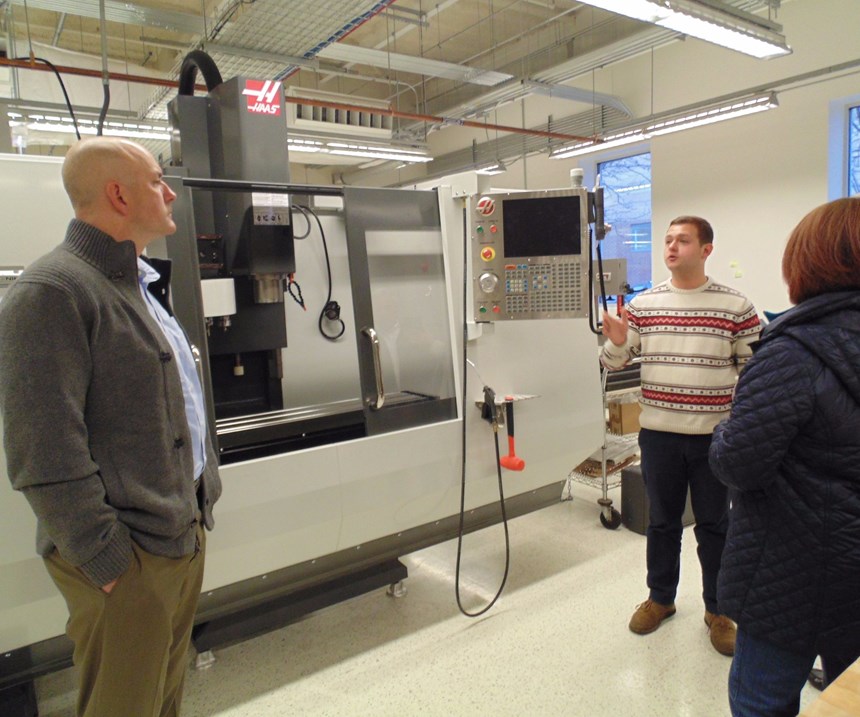

During the tour, which was led by Tyler Bridge, mHUB’s membership development coordinator, the group saw several entrepreneurs developing, building and testing their products. These included items like a unique waterproof brace that can custom fit to a medical patient without 3D printing, ModoBags (the first motorized suitcase), and a safer needle for dentists to use. One gentleman was replicating a classic Motorola radio, designing it to be blue tooth capable. He said he will sell it to companies as a marketing tool. This project was very apropos as mHUB is housed in the old, 63,000-square-foot Motorola facility! The energy and excitement emanating from these entrepreneurs was contagious!

Beyond providing meeting and office space, mHUB provides its members with access to several different resources and tools in its electronics, metal fabrication, CNC machining, 3D printing and plastics (featuring a desktop injection molding machine, a vacuum former and a four-foot-long line-bending table), laser cutting, textiles, wet, testing lab and woodworking labs (yes—that is TEN fabrication labs), all of which enable entrepreneurs, inventors, software developers, artists and others to see their ideas evolve into finished, marketable products.

Uniquely, mHUB provides a place to collaborate with others to solve problems and learn about the many areas of manufacturing. Small and large companies join mHUB to conduct research and development, leverage higher cost savings, and gain faster prototyping turnarounds. Manufacturers are exposed to an IDEA and THINK tank of innovative talent from across Chicagoland. Entrepreneurs gain the expertise of the manufacturers and can access immediate responses and cost-effective solutions for their products. It is a win-win situation for everyone!

“The energy in the building was refreshing,” Petrucci said. “I would have loved an mHUB opportunity when I was in high school or college–just to have access to the other young ‘makers’ with intriguing ideas that would have helped fuel my own manufacturing creativity.”

To learn more about mHUB, visit mHUBChicago.com.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

.jpg;maxWidth=300;quality=90)