Jet Tooling?

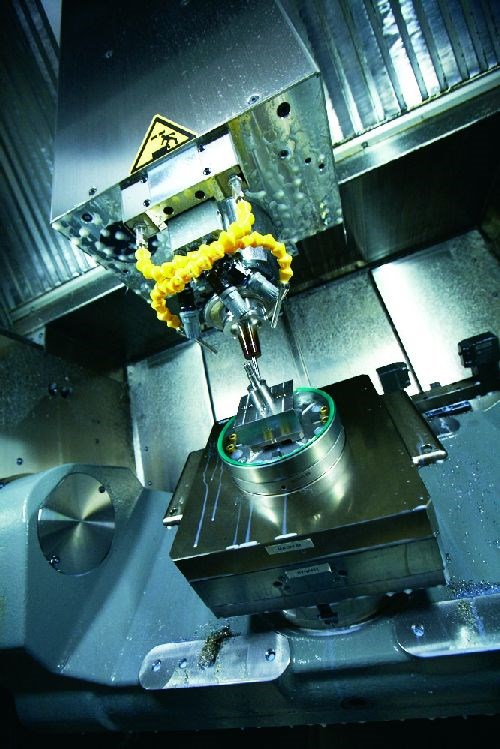

Dedicated tool shop expansion and capital investment into a 5-axis high-speed machining cell with robot tending for lights out 24/7 production, has given Sil-Pro the high-speed capabilities it needs to offer expedited moldmaking services: Jet Tooling.

Sil-Pro is a full-service, medical device contract manufacturer with design, prototype and complete in-house moldmaking capabilities. They have recently announced a new capability to produce tooling and functional prototype silicone or thermoplastic parts within 3 to 5 days: Jet Tooling.

According to Brian Higgins, VP of Sales and Marketing at Sil-Pro, time-to-market pressures from their current medical customer base has pushed the company to offer expedited services that go from print to reliable prototype parts extremely fast.

Sil-Pro’s recent expansion of 25,000 square feet of dedicated tool shop, plus capital investment into a 5-axis high speed machining cell with robot tending for lights out 24/7 production, has given Sil-Pro the the high-speed capabilities it needs for this new offering in expedited moldmaking services.

Sil-Pro has added additional estimating and tooling staff to streamline all internal processes to support the 3-5 day turn around service. Now an engineer can email or upload a Solid Model and Sil-Pro expedites all necessary evaluation, estimating, and final quotation for approval. Once the customer approves the quotation, tool building begins and can be completed within 2 days, and molded prototype parts in 2-3 days.

According to Sil-Pro, Jet Tooling services includes the following benefits: in-house inventory of both pre-hard and hardened stainless steel inserts; wider selection of materials versus other prototype services; can become bridge type tooling to pre-production and smaller production runs; saves money in long run and enhances Design for Manufacturability.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.jpg;maxWidth=300;quality=90)