Is Your Mold Performance and Part Quality Changing During Production Runs?

If so, the ‘key’ to stopping it may be easier than you think.

How frustrating is it when you start up a mold, apply all Scientific Molding principles to your brand-new, all-electric molding machine, and finally get parts approved by the QC department only to have them come back a few hours later and say that some parts are flashing and others are short? Yet nobody has touched the machine and you are still running the same lot of material. So you make some process changes and perhaps can dial in good parts again, only to have the process repeat but this time you can’t fix it.

How do you figure out how to prevent this from happening again? You have to get to the root cause of the issue. Sure there may be band-aids you can put onto the mold to fix it temporarily, but we all know what happens to band-aids—eventually they fall off.

The above scenario may have a multitude of root causes, but knowing how to separate out the variables involved and diagnosing them systematically will go a long way in saving time and money. Here we’ll focus on one of the most simple, yet most unappreciated, root causes of variation over a production run.

Getting to the Root Cause

Many moldmaking shops and molding production facilities like to brag about how well they control their molding operations—pressure transducers, scientific molding, camera monitoring systems, electric molding machines, etc. Although those items are quite impressive and serve good purposes in many applications, there are usually more subtle things at work—such as the runner system that is dangling from a sprue picker and being dropped into a scrap bin or grinder. It is within that runner system where many root causes of variation can be revealed, specifically on the sprue and runner shut-offs within that runner system.

Pressure Loss

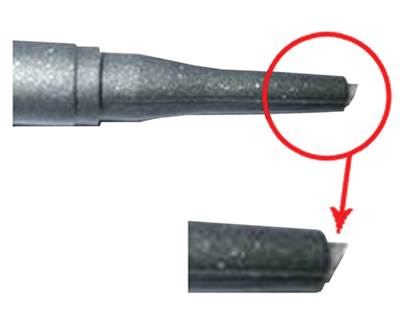

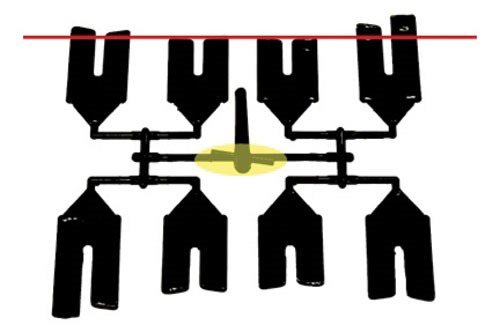

Oftentimes world-class molders have molds running high-precisions parts with runner systems that contain twisted sprue bushings and/or twisted runner shut-offs. Figure 1 shows a picture from a website of a moldmaker touting itself as being a close-tolerance, “attention to details” manufacturer, yet the picture which was meant to highlight their capabilities, shows this simple oversight front and center.

They don’t seem the least bit concerned about it. Why? Because not everyone fully appreciates what the runner system contributes to the overall process window and resulting part quality. Some people turn these on purpose to try to balance the filling of a mold without considering or understanding the ramifications it has on packing the part.

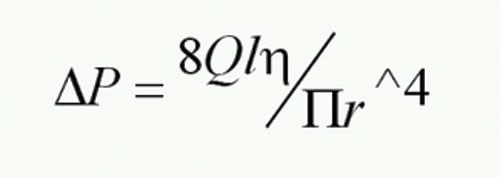

To begin to understand the impact of such a simple problem, we need to understand the variables that affect pressure drop (Pdrop) in a mold. A simplified pressure drop equation is shown in Figure 2. The formula and variables are really quite simple when broken down: Q = flow rate; l = flow length; n = viscosity; r = radius of the flow channel. It is the “r” value that we will focus on here.

The R Variable

So when those tricky sprue bushings and runner shut-offs twist, what happens to the ‘r’ variable? It decreases because you are choking off the flow channel. Then what happens to the Pdrop when the ‘r’ decreases? The pressure drop will increase, and it will increase dramatically as it is raised to the fourth power!

Now you can see that those sprue bushings or shut-offs start to turn gradually throughout the production run causing the Pdrop to also change throughout the run, resulting in the plastic flow being restricted to some areas of mold, which in turn, creates increased flow to other areas of the mold. As such, some cavities may start shorting while others start flashing. The change could be gradual and difficult to detect, but regardless it is changing your process and molded part quality.

Separating the Variables

Of course twisted sprue bushings and runner shut-offs are not the only factors that contribute to filling imbalances. You must be able to sort through all the noise and data to what makes sense. A systematic approach to diagnosing mold filling and part quality variations goes a long way.

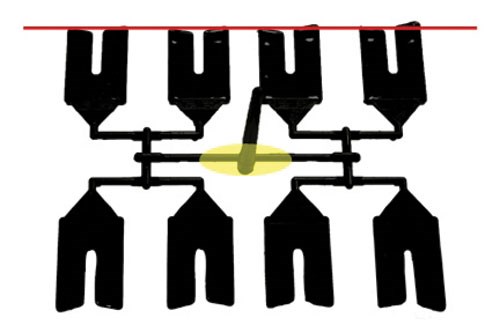

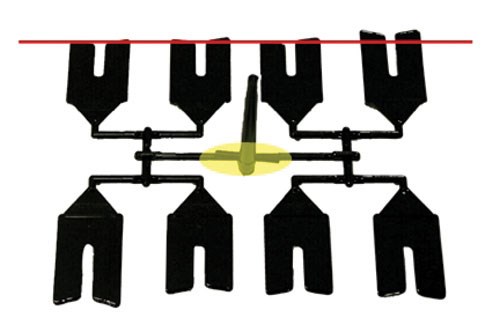

Even a mold that is balanced with rheological control systems can still have imbalance issues due to other variables. Figure 3a shows a short shot of an 8-cavity mold balanced with rheological control. Figures 3b,c show two other short shot analyses where the filling is no longer balanced. A few cavities are now filling much faster than the others. This was accomplished (on purpose for demonstration only) by slightly rotating the sprue bushing at varying degrees to demonstrate how easily this can happen on the shop floor and the impact it can have on filling and part quality.

The Key to Fixing the Problem

Now that you know these simple factors in our complex mold should not be ignored, how do you fix the root cause? The key to fixing the sprue and runner shut-off issue could be as simple as a key itself. Key the sprue bushing and key the runner shut-offs.

As for runner shut-offs, some off-the-shelf designs apparently work better than others. Do some research and testing internally to find out what fits your needs. And yes, it is understood that one of the nice benefits of runner shut-offs is to be able to quickly shut-off flow to a cavity or cavities, so does keying defeat this purpose? No, because you should not need to be adjusting them on a daily basis. If you are, you need to fix the root cause. So whether making your own or purchasing off-the-shelf items, try to put in provisions for keying. It will save a lot of headaches down the road.

And finally, the sprue bushing only needs to be keyed if it has runner geometry cut into it or if it is a ported hot sprue bushing, but that is a story for another time.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MorePortable Low-Heat, Non-Arcing Resistance Welder for Mold Repair

Rocklin’s user-friendly MoldMender Micro Welder delivers simple and cost-effective localized repair in-house with precision and versatility, enhancing mold and die durability and reducing disassembly and downtime.

Read MoreRead Next

How to Systematically Diagnose Mold Issues and Part Quality Variations

Apply fundamental plastic flow principles to troubleshoot your mold’s problems.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)