Internal Threading Made Easy

New advances in thread milling technology allow moldmakers to meet the challenges of threading difficult materials.

The features and performance of modern machining centers have created the opportunity for the use of a new generation of solid carbide thread mills. Machine tools now have the computer power, flexibility and mechanical reliability to generate three-axis toolpaths at high speeds with superior accuracy and efficiency. As the synchronous tapping cycle redefined the application of taps, advances in three-axis helical interpolation have given rise to new threading solutions.

The new developments in thread milling technology are reflective of the ever-increasing demands on manufacturers to reduce operating costs, improve part quality and enhance profitability. And when it comes to the mold and die industry, new tooling solutions were necessary to solve the long-standing daily challenges of threading difficult materials such as alloy steels, tool steels and stainless steels. In addition, with a growing number of mold shops incorporating hard milling, new thread cutting tools were required to economically produce threads in finished parts heat treated up to 60 Rc.

A Thrilling Technology

Thread milling and circular thrilling - the process of drilling and thread milling simultaneously - are becoming popular machining techniques because they significantly reduce manufacturing costs while producing superior quality threads when compared to conventional tapping methods. The exceptional performance is achieved by combining select micro-grain carbide, advanced cutting geometries, multiple flutes, select PVD coating and internal coolant supply. Advanced thread milling technology offers long tool life, process control, flexibility, precision and value. The following are just a few of the many benefits this new generation of carbide thread mills offers when matched with a modern CNC machine.

- Easy machining of difficult materials up to 60 Rc.

- Produces threads with excellent form, finish and dimensional accuracy.

- Eliminates the possibilities and consequences of tap breakage.

- Multi-functional circular thrillers reduce cycle times by combining drilling and threading operations into one tool.

- Pitch diameter can be controlled by CNC offset. (Eliminates oversize machine taps.)

- Optimum positional accuracy.

- Precise thread depth control.

- Full bottom threading. (Eliminates hand tapping operations.)

- One tool for through or blind holes.

- One thread mill can produce varying thread diameters of the same pitch.

- One tool for right-hand and left-hand threads.

- Produces small, controllable chips. (No bird nesting.)

- Smaller machines can produce larger threads due to less spindle torque.

- Less cutting pressure for thin-walled workpieces.

- No high-performance lubricants are required. (Eliminates stopping machine to apply lubricants by hand.)

Key Developments

The key developments in new thread milling technology comprise four product categories that can produce an extensive variety of thread types and sizes. They can be used in all materials with superior economic efficiency when compared to traditional tapping methods. These are pitch specific thread mills, thread mills with chamfer function, taper pipe thread mills and circular thrillers.

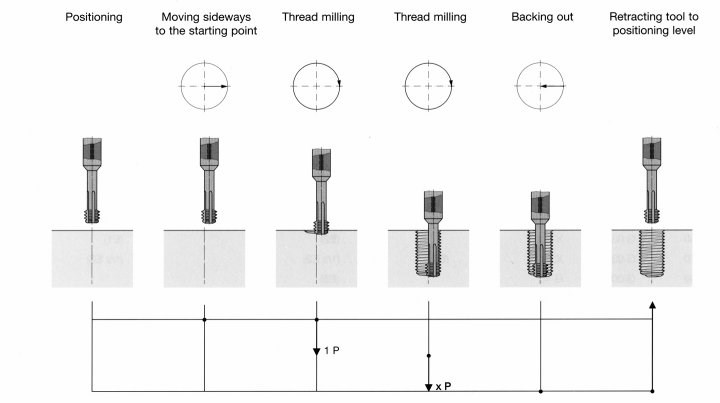

Pitch Specific Thread Mill

Pitch specific (1/18 UN, 1/20 UN, etc.) solid carbide thread mills are used for the production of thread diameters 1/2" or larger in all materials to up 52 Rc. One thread mill can produce a variety of thread diameters of the same pitch with a simple modification of the CNC program. Drilling and chamfering of the hole is required (see Figures 1a and 1b).

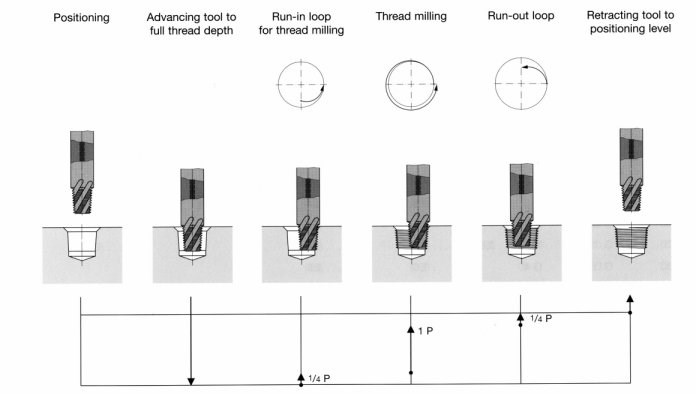

Taper Pipe Thread Mill

Solid carbide thread mills are used for the production of taper pipe threads NPT, NPTF and BSPT. Sizes 1/16" thru 2.0" can be produced in all materials up to 52 Rc. Drilling of the hole is required (see Figures 2a and 2b).

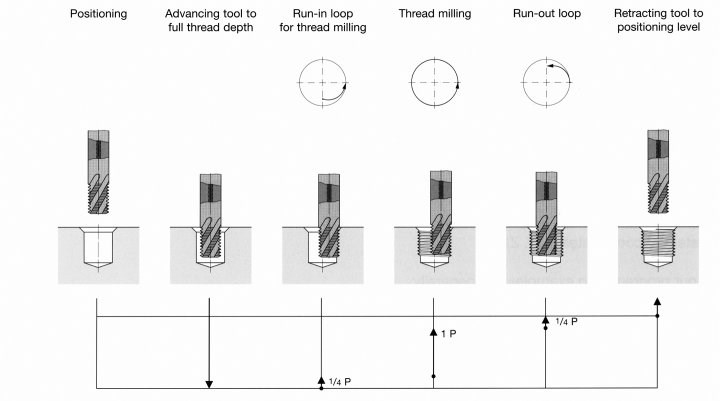

Thread Mill With Chamfer Function

Solid carbide thread mills with chamfering function are used for thread sizes #10 thru 3/4". Thread mills with chamfer are special ground with an enlarged cutter diameter that is specific to a thread size and pitch (#10-32 UNF, 1/4-20 UNC, etc.) for increased cutter strength. They can be used in all materials up to 52 Rc. Drilling of the hole is required (see Figures 3a and 3b).

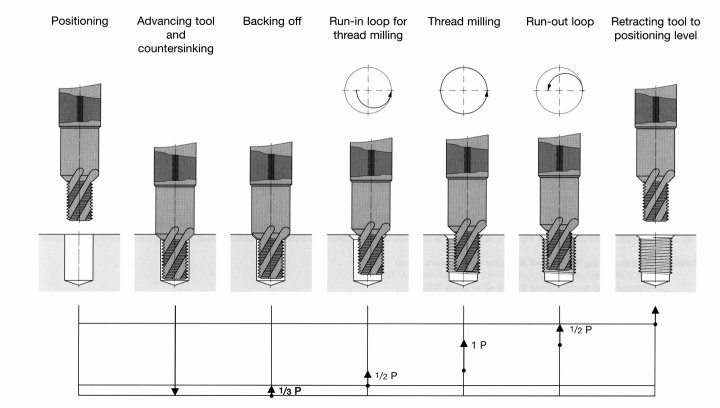

Circular Thriller

Solid carbide thread mills with drilling function are used for sizes 1/4" through 3/4" for all materials up to 60 Rc. From solid material, the circular thriller can drill and thread in one pass. Through-spindle coolant is required on the CNC machine for proper function (see Figures 4a and 4b).

In an era when global competition is changing the rules of competitiveness in the mold and die industry, leveraging the cost reduction benefits of advanced cutting tool technology has never been more important. Be sure to work with your supplier, as technical support and programming services can take manufacturers straight to production quickly and efficiently. In addition, thread mills that can easily be set up and programmed for a wide range of threading applications can immediately transform threading challenges into profits.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)