How to Compete in the Global Marketplace

A new program gives moldmakers the opportunity to learn business strategies that will help their company thrive.

Gone are the days when contracts were sealed with a handshake, customers were plentiful and business seemed to grow like a weed if you had a desirable product or service to sell. Thanks in large part to the Internet, the world is much smaller now, and countries like China, Mexico, Taiwan and Canada are ready and willing to lure once loyal customers to their shores with the promise of cheaper prices and comparable quality.

Stepping up to help Chicago-area manufacturing companies compete more effectively in the global marketplace, the Illinois Institute of Technology (IIT) (Chicago, IL), the Tooling & Manufacturing Association (TMA) (Park Ridge, IL) and LBL Strategies, Ltd. (Chicago, IL) have formed a strategic partnership to offer a newly accredited, award-winning course entitled The Certificate in Strategic Management Program.

Winner of the Exemplar Award of the International Association for Continuing Education and Training (IACET), the program's central theme is to help progressive manufacturers focus, make better business decisions and grow. It is aimed at business owners, presidents, CEOs, CFOs, CIOs, controllers and marketing, human resources, operations/production managers and other key staff.

Not Your Ordinary Class Format

"The Certificate in Strategic Management program offers a platform and a method for business owners to develop plans that move them from reactive to proactive modes," says TMA President Bruce Braker. "This isn't a program that simply teaches how to develop a strategy; it actually takes the management team through the process of developing and implementing the strategy that works best for their particular company."

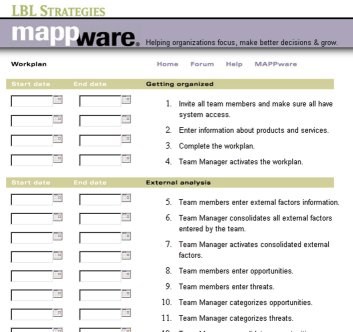

The Certificate in Strategic Management Program is not a passive classroom course for one employee to attend and report back to their company executives. It is conducted in a very hands-on format designed for teams of three to six persons to work together, actually breaking down their company through the careful examination of the industry, their markets and major internal processes that affect growth, resources and profitability. By the end of the course, the team will generate a strategic plan designed to position the company for success.

Students from IIT's Manufacturing Productivity programs will participate in the course by conducting research and helping assemble the information that participating businesses need to refine their business strategies and thrive. The students will earn academic credit in the class, and IIT will award certificates to manufacturers who complete the eight half-day sessions. "Allying with a university such as IIT is a good thing," says Keith McKee, Ph.D., director of the Manufacturing Productivity Center. "For-credit courses automatically have the college's reputation behind them. If you really want to look at where your company is at, you have to do something like strategic planning. The majority of students here do have experience working in companies and the course will help them see their companies from a different point of view - kind of like getting a clean pair of glasses."

MAPPwareT Makes the Difference

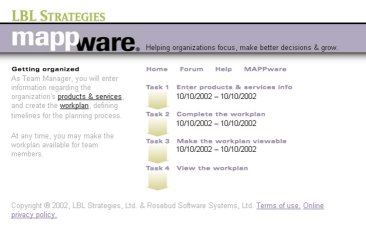

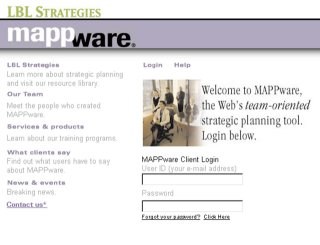

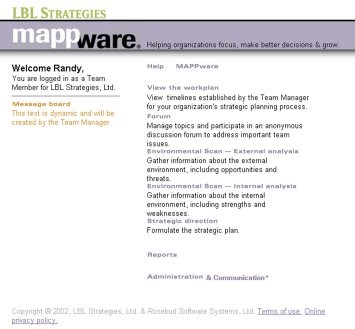

Randy Rollinson, president of LBL Strategies, Ltd., developed the Certificate in Strategic Management Program and will lead the course. Rollinson is an adjunct faculty member at IIT, and has been an adjunct faculty member at the University of Illinois at Chicago since 1991. LBL Strategies, together with partner company Rosebud Software Systems, Ltd., has provided strategic management services to more than 2,500 businesses and organizations since 1985, and has developed a web-based strategy development tool called MAPPware, which will be used by participants in the program. It is MAPPware that helps set this program apart from any other management program.

"MAPPware is an easy-to-use, executive management tool that streamlines the strategic planning process among executives, departments and business units by supporting communication, collaboration and maximum leveraging of organization knowledge," says Rollinson. "MAPPware is a user-friendly, guided application that allows any designated user to participate in a robust planning process anywhere and anytime there is Internet access."

"The challenge of doing business in today's marketplace is enormous," Rollinson continues. "It's a tough balancing act managing the day-to-day while keeping a wary eye on evolving trends and future markets. The pace of change demands constant skill sharpening in assessing opportunities and targeting resources based on a solid understanding of what you do best and how to leverage it. The Certificate in Strategic Management Program, with MAPPware, provides a clear route to finding and implementing the business strategies manufacturers need to thrive. The beauty of it is that the program tools, including MAPPware, can be used well beyond the end of the course to ensure continuity and growth as the marketplace evolves."

A Program With Documented Results

Several manufacturers have enlisted in and completed the program over the last two years, even before IIT joined in partnership with the TMA and LBL Strategies. Several more are working through it now on an in-house basis, where Rollinson and his staff conduct the sessions in a more private setting at each company's headquarters. Companies that have completed the program are singing its praises and several are seeing very positive results - even in today's difficult times.

One company reported growing its business more than 135 percent in fiscal 2000. Yet another said it had the second best year in its history - and that was after having a losing year just previous to taking the Strategic Management Program. Rollinson admits these are exceptional results, but that any company can achieve them. One would be hard put to find a company that has gone through the program and doesn't have praise for how it has affected the way the company operates and is moving forward instead of back.

Many cited the benefits of looking at themselves not only from an internal perspective, but also externally via an environmental scan, examining the state of their respective industries, trends in technology and customer demands, political and economic influences and other important factors. Team members assess individually and collectively the meaning of the scan for their company, taking critical data and developing what will be a SWOT analysis, or a comprehensive list of the company's strengths, weaknesses, opportunities and threats. This process forms the basis for companies to then move into the strategic planning stages of the program. It literally opens the team up to very active and insightful discussions about the company's goals and how it will best achieve them based on what is learned from the environmental scan and SWOT analysis, and from using other important tools of the program.

"The environmental scan process helped us to recognize how important it is to continuously learn what is happening outside the company so we can adapt," says Janice Nieman, vice president of CGI Automated Manufacturing (Cicero, IL) - whose experience includes fixtures, enclosures and other parts for a wide variety of industries including pharmaceutical, electronic, communications, railcar, lighting, food processing and store fixtures. "It helped to give us an approach that allows us to better analyze our industry and recognize new opportunities. Too often, companies focus internally on strengths and weaknesses. The program really pulled us together as a team to create a better strategy, and gave us measures to ensure our progress."

"We found the program very well organized and structured," notes Dave Anderson, human resources director at P-K Tool & Manufacturing Co. (Chicago, IL), whose line of services includes tooling and design, metal stampings, production and assembly and production machining. "Each session, each exercise built on previous work. We could really see how the pieces fit together. The assignments were valuable and very practical. Doing the strengths, weaknesses, opportunities and threats analysis really gets you thinking. It gives you a very structured approach to developing a strategy that you would not have otherwise developed. Everyone knows you need to plan, but most of us don't know how to get started. This program answers the question, 'What do I do first?'"

The Certificate in Strategic Management program will begin in January 2003 and will be offered at both the TMA Training Center in Park Ridge, IL, and on-site at company locations. Registration for the first session runs through December 15. Space and management team size is limited depending on where a company elects to take the course.

The cost of the course varies and is based on whether the company opts for in-house or TMA-based classes. Enrollees also may be eligible for subsidized course funding through the Department of Communications and Community Affairs' Industrial Training Program (ITP) and should inquire about this when they call for information.

Related Content

Strategies for Delivering a Qualified Talent Pipeline for Manufacturers

Insights into the importance of talent in maintaining national competitiveness, the impact of global events on the workforce and practical strategies for developing and implementing effective talent plans.

Read MoreCertified Quality Management for Plastics Professionals – Materials to Tooling to Recycling

Why is certification of a shop’s quality management system to ISO 9001, AS9100, IATF 16949 or ISO 13485 so special? What does the certification signify? And what supports the paper behind the framed certificate?

Read MoreMMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreFAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreRead Next

Molder’s Message to Foreign Competitors: ‘Bring It On!’

An inspired combination of automation, ISO certification, use of certified resins, and strict adherence to a rigorous set of time-honed manufacturing standards are among the chief factors giving the Rodon Group, a 54-year-old custom molding operation in Hatfield, Pa., the confidence to boast that it can beat the pants off of Chinese part pricing, and Mexican pricing, too.And it’s not an idle boast.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More