SLIDESHOW: A Holy Mission to Introduce Kids to the Trades

When I think of my Aunt Jo now, I often wonder if we had talked more about our jobs 20 years ago, we would have come up with a way to work together to make a difference locally in filling the skills gap. So, I encourage you to shout from the rooftops about what you do, so you don’t miss an opportunity to open the door for someone to enter the trades.

Ever have that relative whose profession was a mystery growing up? Heck, my dad was an electrical engineer for a vacuum pump systems manufacturer who loved being out on the shop floor, and I didn’t know that until I was an adult. Little did I know that a few years later I’d be covering the trades in the manufacturing media, and then unexpectedly bump into my father at a local tabletop trade show. Too funny.

Well, it happened to me again. This time more recently. And, I want you to understand that I come from a big family who always got together, but I guess I grew up in an age where the adults didn’t sit around talking … or complaining … about work stress like we seem to do today (at least that’s what my nieces and nephews tell me). So, not having a clue what relatives did for a living was pretty common.

This time the relative is my late Aunt Jo (or as most referred to her, Sister Raymond Mary Cline, a Sister of Mercy). In 1973 she began 35 years of service to Mercy Vocational High School where she taught business education and computer technology. In 1999 she made a move into the career services department as an assistant to the director of cooperative education.

This was a year into MoldMaking Technology’s life and I still was not fully aware of what she was doing, how important it was and how closely tied it was to my career … helping to educate mold manufacturing professionals and making connections to help fill the skills gap.

My aunt used her position there to focus on on-the-job learning for students, which often landed them full-time employment after graduation. She also launched a "shadow" program through which students would follow professionals, observe them working and asking questions. She was constantly celebrating Manufacturing Day.

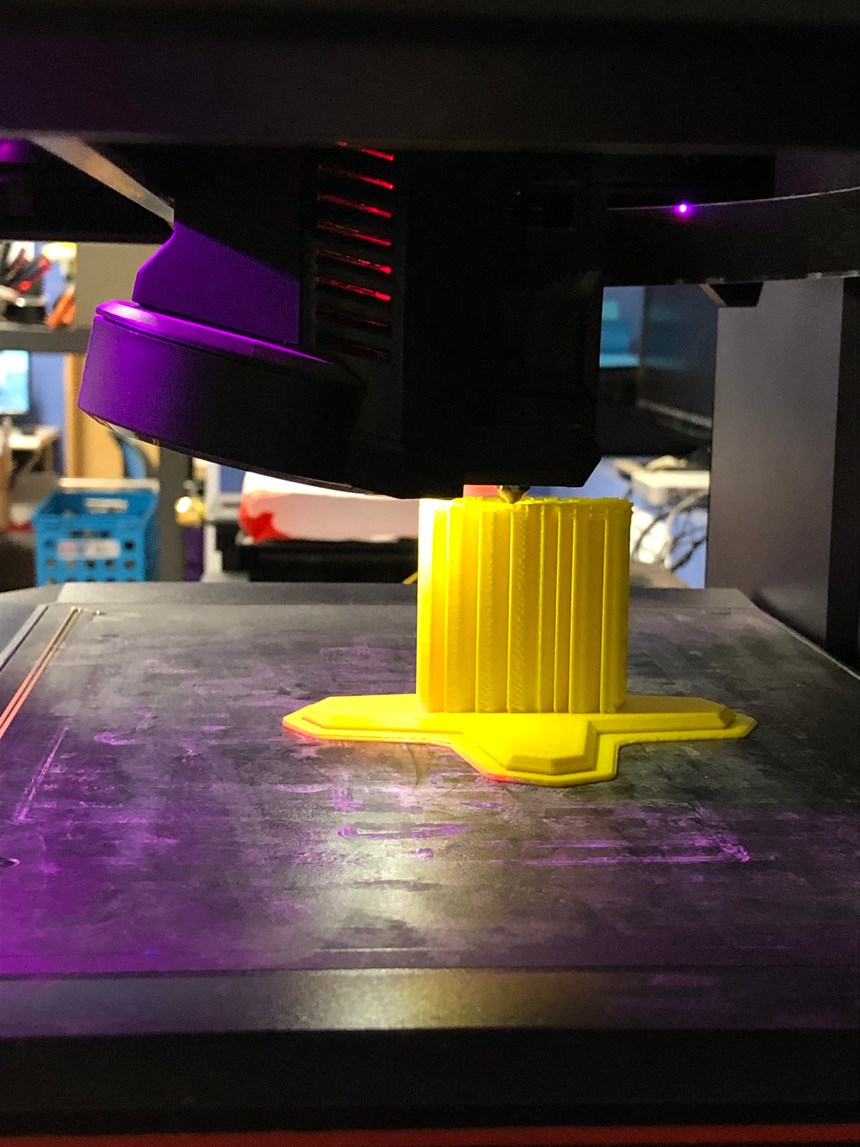

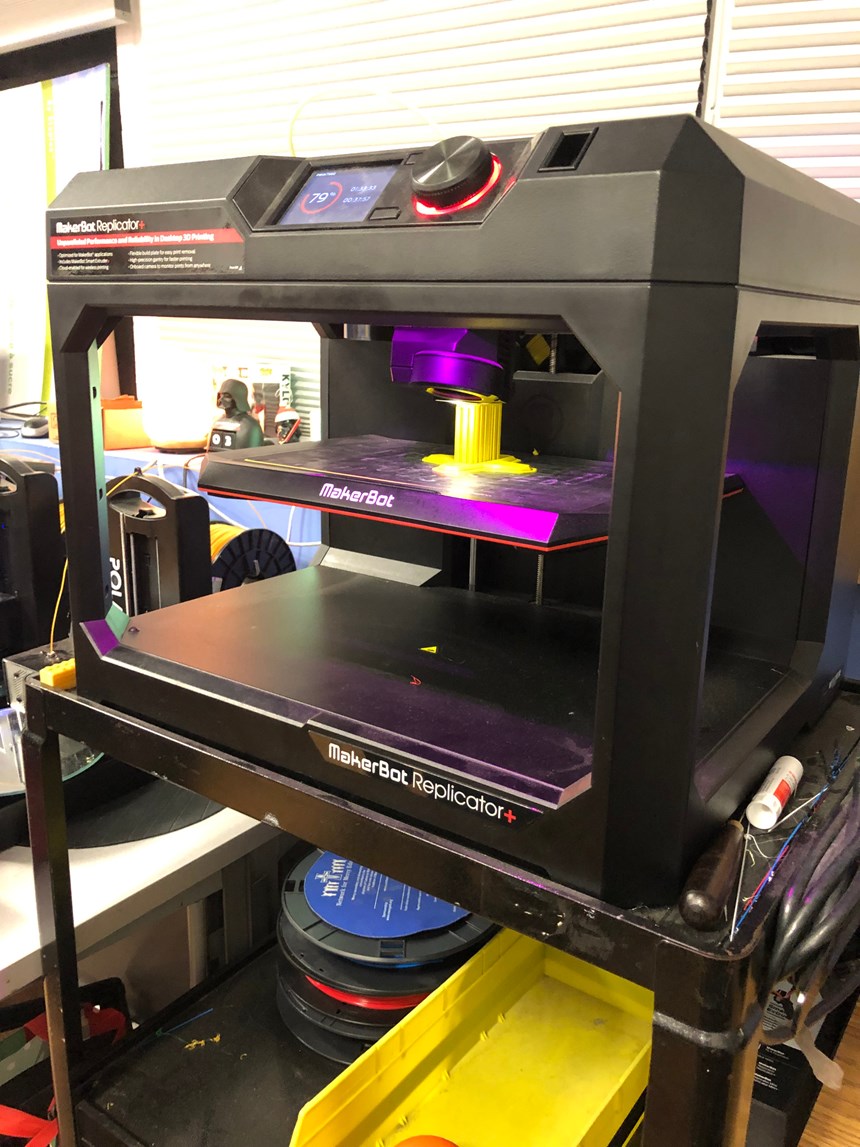

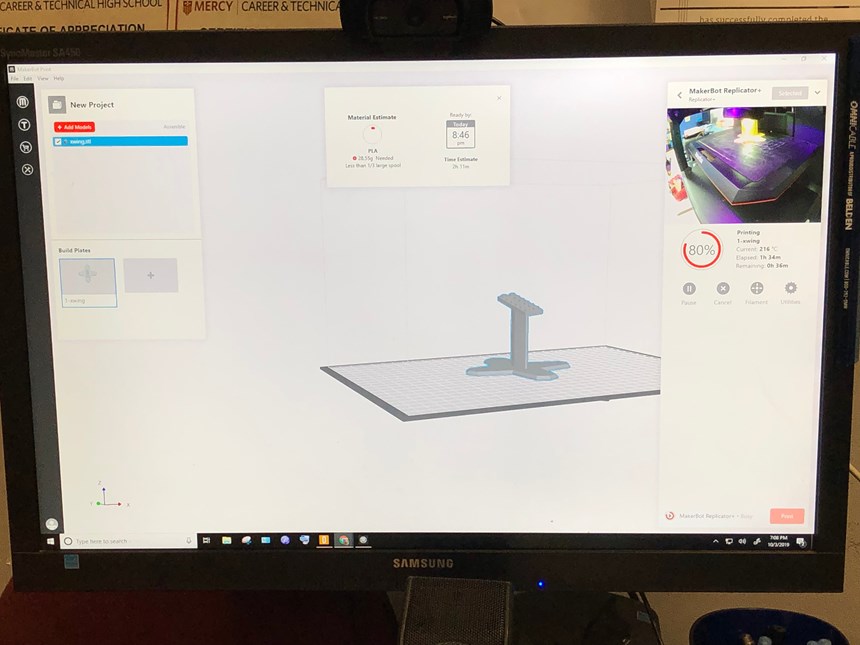

My aunt passed away a few years ago, but her legacy lives on at Mercy Tech. I share this story because I recently visited Mercy Tech and saw how much the program has grown. I also had the opportunity to meet some amazing young students who are falling in love with the trades. (And if you are a Top Chef fan, it didn’t hurt that during that visit I got to meet Eddie Conrad, a Mercy Tech alumnus).

Mercy Tech & Mercy Vocational High School

This experience has taught me to speak up more about the trades to family, friends, and neighbors, so they better understand what I do for a living and the awesome career opportunities the moldmaking industry has to offer. It is part of my job to do so, and it starts at home!

When I think of my Aunt Jo now, I often wonder if we had talked more or shared more deeply about our jobs 20 years ago, we would have bonded over our passion for the trades, and perhaps come up with a way to work together to make a difference locally in filling the skills gap.

So, I encourage you to shout from the rooftops about what you do, so you don’t miss an opportunity to open the door for someone to enter the trades.

And while I’m at it, mark your calendars for Amerimold 2020, June 10-11 in Novi, Michigan during which we are launching a Resource Fair on the show floor focused on unexplored sources of talent.

Related Content

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More